Differences between spectral and white light interferometric thickness measurement

Spectral Thickness Measurement (usually using a spectral confocal sensor) and White Light Interferometric Thickness Measurement (usually using a white light interferometric thickness measurement sensor) are two different thickness measurement solutions. The following is an analysis of the two based on their principles, scope of application and accuracy.

Principle:

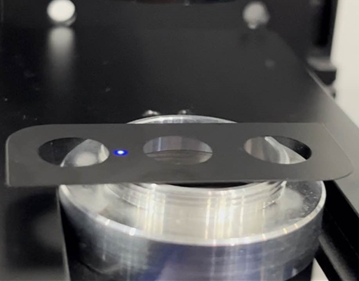

Spectral alignment thickness measurement spectral confocal sensor uses a light source (usually a white light source) through the coupler and a dispersive objective lens to hit the light, dispersive objective lens will be different colors of light classification and focusing to a different fixed position, when the object is located in a certain light focusing position, the photon intensity of the light is the largest, through the optical path back to the light will be entered into the spectrometer for judgment, detection of the frequency of the backscattered light change to measure the material Thickness.

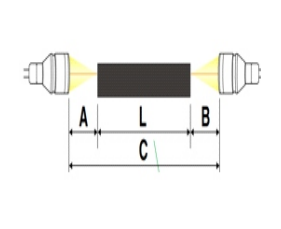

White Light Interferometric Thickness Measurement: White light interferometric thickness measurement sensors work on the basis of the optical interference principle; the light emitted from a white light source is divided into two parts, one part is reflected directly to the interferometer as reference light, and the other part strikes the surface of the object to be measured as measurement light. At each interface of a transparent coating (e.g. air-coating, coating-substrate), a part of the measuring light is reflected back, and interference occurs between these reflected lights. Analyzing the changes in the interference pattern, the thickness of the object can be accurately calculated.

Applicable range and accuracy:

Spectral Thickness Measurement: suitable for thicker coatings, with a wide measuring range (e.g. 50um-10mm) and high accuracy (up to 0.5um). For ultra-thin coatings (e.g., thin coatings used in some high-end electronics), the accuracy of spectral confocal sensors may not meet the requirements.

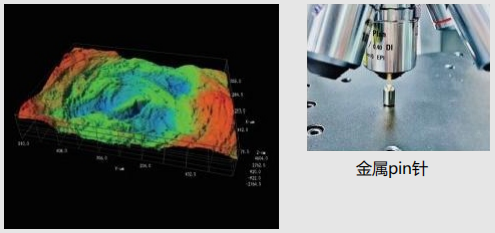

White Light Interferometric Thickness Measurement: Suitable for the measurement of ultra-thin coatings, the measurement range is usually between 1-100um, and can even measure coatings of 100-1000nm nanometer thickness. Measurement accuracy is very high and can reach 1nm nanometer level.

Advantages of both:

Non-contact measurement: both solutions avoid sample damage or contamination that may result from physical contact.

Fast measurements: Both spectral and white light interferometric thickness measurements can be done in a shorter period of time compared to traditional methods.

Spectral and white light interferometry have their own characteristics and applications. Spectral thickness measurement is suitable for thicker coatings, with a wide measurement range and high accuracy, while white light interferometric thickness measurement is more suitable for ultra-thin coatings, with very high measurement accuracy. When choosing a thickness measurement solution, it is important to select the right equipment based on the specific measurement needs and coating thickness.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com