Application of Image Dimensioning Instruments in the Measurement of Radiator Housings

With the continuous development of modern industrial technology, the manufacturing precision and size requirements of radiator shells are getting higher and higher. Traditional measurement methods, such as vernier calipers, micrometers, etc., although to a certain extent to meet the measurement needs, but in the face of high-volume, high-precision, complex shapes of the radiator shell measurement, it seems to be incompetent. Therefore, as an advanced non-contact measuring equipment, image size measuring instrument (flash meter) is gradually widely used in the field of radiator shell measurement.

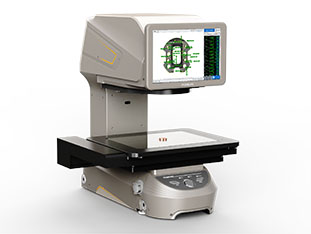

POMEAS Image Dimension Measuring Instruments (Flash Measuring Instruments) Image 3 series is a measuring device based on machine vision technology, which utilizes a high-resolution camera and image processing algorithms to perform fast and accurate dimensional measurements of the object under test. Compared with traditional measurement methods, the flash meter has the advantages of fast measurement speed, high accuracy and easy operation, which is especially suitable for the measurement of large quantities, high precision and complex shape objects.

Measurement requirements:

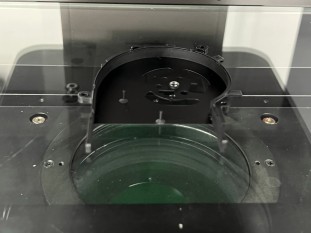

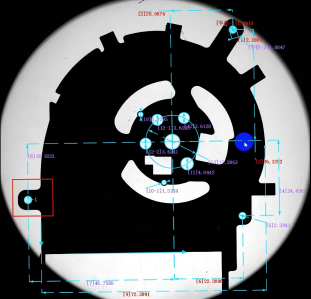

As an important part of electronic equipment, the dimensional accuracy of the radiator shell directly affects the heat dissipation effect and overall performance of the equipment. Therefore, in the production process of the radiator shell, it is necessary to carry out strict dimensional measurements. Measurements include, but are not limited to, key dimensions such as the length, width, height, thickness, aperture diameter of the shell, as well as the precision requirements of shape and position.

Application of flash meters to radiator shell measurements:

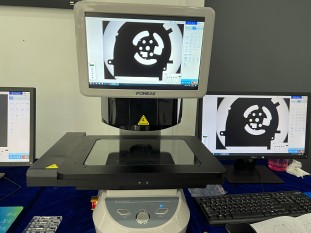

1. Fast measurement: flash meter adopts non-contact measurement method, can complete the measurement of a large number of radiator shells in a short period of time, greatly improving the measurement efficiency.

2. High-precision measurement: flash meter using high-resolution cameras and advanced image processing algorithms, can realize the size of the radiator shell micron-level measurement, to ensure the accuracy of the measurement results.

3. Automated measurement: flash meter is usually equipped with automated measurement system, can automatically complete the measurement task, reduce human intervention, improve the consistency and stability of the measurement.

4. Multi-functional measurement: flash meter can not only measure the basic dimensions of the radiator shell, but also its shape, position and other complex features to meet the diverse measurement needs.

Measurements:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com