MetX measurement software to help upgrade cell phone center frame inspection!

The rapid development and fierce competition in the cell phone industry have made cell phone manufacturers demand more and more for product quality and production efficiency. Among them, the center frame of a cell phone, as the main structural component of a cell phone, the accuracy of its contour dimensions directly affects the quality and performance of the product. Through accurate measurement, we can ensure that the dimensions of each batch of products are consistent, thus improving the quality and performance of the products.

The MetX measurement software of POMEAS adopts OS/APP architecture, which is compatible with multiple functional modules such as dimensional measurement, sensor measurement, contour inspection, vision inspection, etc., and can be switched flexibly according to the needs. Meanwhile, the software also supports a variety of measurement sensors, which makes the measurement more comprehensive and the operation simpler, and improves the measurement efficiency greatly.

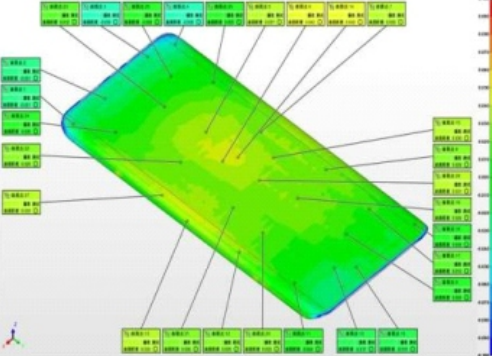

For the inspection of cell phone mid-frame contours, the 3D surface contours and truncated contours of cell phone mid-frames can be inspected by using the POMEAS Met X measurement software with a line laser sensor.

Detection process:

Equipped with a single-axis mobile platform, the line laser sensor can acquire the point cloud of all the features of the product surface through mobile acquisition, and compare the point cloud data with the standard data to realize 3D face contour inspection and truncated line contour inspection of the product.

Program Strengths:

1.The software can automatically find the edge to scan the whole closed curve of the cell phone center frame, and do the contour comparison with the imported CAD theoretical curve, and output the graphic report.

2. The high measurement accuracy of the POMEAS line laser sensor can realize micron-level resolution, which can accurately measure the small changes on the surface of the object.

3. Non-contact measurement to avoid detection errors and wear and tear that may be caused by contact measurement.

4. The software interface is simple and easy to understand, the operation is quick, easy and fast to complete the measurement configuration.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION