What are the application scenarios of in-line gauges in the metal measuring industry?

The application scenarios for in-line gauges in the measurement of metal parts are wide and varied, and are characterized by the following aspects:

Rolling, casting: In the production process of rolling, casting or forging of metal products, it is necessary to monitor the thickness, width, length and other dimensions of metal materials in real time. Online measuring instrument can quickly and accurately obtain these key dimensional data to ensure the stability of the production process and product quality consistency. For example, in the steel plate rolling process, through the real-time monitoring of the online measuring instrument, the deviation in the rolling process can be detected and corrected in time to ensure the thickness accuracy and surface quality of the steel plate.

Quality inspection: In the quality inspection of metal products, online measuring instrument also plays an important role. It can carry out comprehensive inspection on the geometric size, shape accuracy, surface roughness, etc. of metal products to ensure that the products meet the design requirements and quality standards. This is important for improving product quality and customer satisfaction.

Automated production line: In-line measuring instrument is also widely used in the automated production line of metal parts. By linking with other equipment on the production line, it realizes the organic combination of online measurement and automation control. This not only improves production efficiency and reduces labor costs, but also reduces measurement errors caused by human factors and improves measurement accuracy and reliability.

R & D and innovation: online measurement instrument also plays an important role in the development and innovation process of metal parts. Through accurate measurement and analysis of metal parts, it can provide powerful data support for product development and promote product optimization and improvement.

Among the many brands of in-line gauges, POMEAS in-line gauges stand out with their unique advantages. The following are some of the significant advantages of Bumis in-line gauges in the field of metal parts measurement:

1、High-precision measurement: POMEAS in-line gauges are capable of high-precision measurement. It adopts advanced sensing technology and data processing algorithms to realize precise measurement of metal parts with a high accuracy of ±2μm, ensuring the accuracy and reliability of the measurement results.

2、Fast Measurement: POMEAS in-line gauges are characterized by high efficiency and fast measurement speeds. By optimizing the measurement algorithm and adopting high-performance hardware devices, POMEAS in-line gauges are able to complete the measurement of metal parts in a short period of time, which meets the real-time monitoring needs of production lines.

3、Automated Calibration and Adaptive Adjustment: The POMEAS in-line gauge is also equipped with automated calibration and adaptive adjustment functions. It is capable of automatic calibration to ensure the accuracy and stability of the measurement, as well as adaptive adjustment based on real-time measurement data to meet the measurement needs of different metal parts.

4、Easy to operate: The operation of POMEAS Online Gauge is simple and user-friendly. Anyone can easily set up and measure, and its measurement results are automatically saved, and the report can be exported with one click, which is easy to analyze the results and trace the management.

With the advantages of high accuracy, high efficiency, automated calibration and easy operation in the field of metal parts measurement, POMEAS in-line measuring instrument provides strong support for metal parts production, quality inspection, automated production lines and product development. Whether you are a large manufacturing company or a small workshop, a Bumis in-line gauge can be an indispensable measurement tool for you.

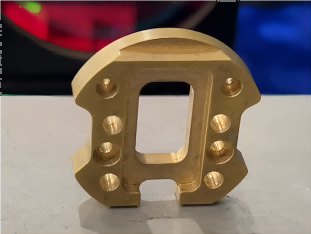

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com