On-line measuring instruments: efficient guardians of the production line

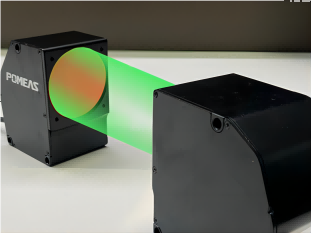

In today's highly automated manufacturing industry, the improvement of production efficiency and product quality is the key to the sustainable development of enterprises. With its excellent performance and innovative technology, POMEAS in-line measuring instruments have become the right-hand man on the production line, providing accurate and efficient measurement solutions for automotive manufacturing, electronics manufacturing, machining and many other fields.

Automobile Manufacturing:In the production process of automotive parts, the requirements for dimensional accuracy and shape tolerance are extremely strict. POMEAS in-line measuring instruments can measure key components such as engine blocks, crankshafts, pistons, etc. in real time to ensure the consistency and assembly accuracy of the components, thus improving the overall performance and safety of the automobile.

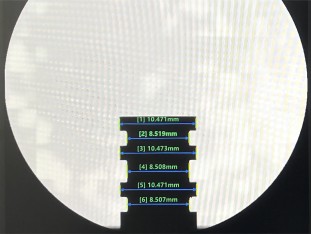

Electronics Manufacture:The trend of miniaturization and refinement of electronic products has put forward higher requirements for manufacturing processes. In-line measuring instruments can accurately measure the dimensions and positional parameters of electronic chips, circuit boards, connectors and other tiny components, providing a guarantee for the high-quality production of electronic products.

Machining:During the machining process of mechanical parts, POMEAS online measuring instrument can monitor the dimensional changes of the workpiece in real time, adjust the machining parameters in time, avoid the production of scrap, and improve the precision and efficiency of machining.

The POMEAS In-Line Gauge has excellent integration capabilities with production line automation equipment. It can be seamlessly connected with CNC machine tools, robots, conveyor lines and other equipment to realize real-time data transmission and sharing. Through the close integration with production lines, the in-line measuring instrument can provide real-time feedback of measurement data to help production equipment adjust processing parameters in time to realize intelligent production.

This real-time measurement and feedback mechanism greatly improves production efficiency. Adjustments in the production process are more timely and accurate, reducing the generation of scrap due to dimensional deviations and lowering the scrap rate. At the same time, it reduces the time and error of manual measurement, improves the degree of automation and stability of production, reduces the production cost for the enterprise, and enhances the market competitiveness.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION