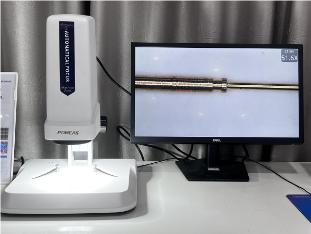

In the field of precision inspection, light source design directly impacts imaging quality and inspection efficiency. The POMEAS motorized zoom autofocus microscope overcomes the limitations of traditional single-light-source systems through innovative four-zone illumination technology, achieving full-scenario adaptability from industrial quality control to scientific research observation. Let's explore this autofocus microscope's new capabilities through three dimensions: technical principles, core advantages, and application cases.

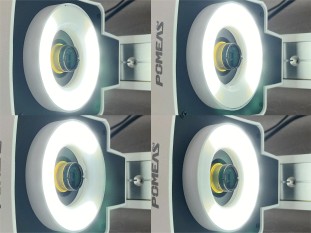

Technical Principle: Zone-Controllable Smart Lighting System

The four-zone light source divides the ring light into four independently controllable quadrants, each with adjustable brightness. This design leverages machine vision photometric stereoscopy algorithms to capture surface information through multi-directional illumination. For instance, in metal surface inspection, high brightness in the upper-left quadrant enhances scratch contrast while low brightness in the lower-right quadrant reduces glare interference—enabling precise lighting control where needed. Compared to the uniform illumination of traditional ring lights, the four-zone technology prevents overexposure and shadows through zoned adjustments. It is particularly suitable for inspecting highly reflective materials such as stainless steel and glass.

Case Study:

Core Competitive Advantages

1. Eliminate lighting blind spots: Traditional single light sources often create dark areas on curved or irregular surfaces. The four-zone lighting system ensures uniform illumination from every angle through zoned supplemental lighting. In wafer tray inspection, this system covers micron-level defect detection across a 0.7x-4.5x wide magnification range, preventing missed defects due to uneven lighting.

2. Enhanced Defect Recognition: Zone-specific brightness adjustment highlights feature contrast in targeted areas. For instance, in PCB solder joint inspection, adjusting diagonal zone brightness sharpens solder joint contours. In metal dimple detection, zone illumination combined with 2.5D image processing converts minute surface irregularities into clear visual data.

3. Adapting to Complex Scenarios: For low-contrast scenarios like internal characters on plastic bottle caps or steel stamps on toothpaste packaging, the four-zone light source achieves detail capture beyond traditional lighting through high-speed zone-specific brightness boosts and software synthesis. Shanghai Kaiwei Optoelectronics case studies demonstrate that pairing the four-zone ring light with a brightness-boosting programmable power supply can elevate light intensity to 10-40 times conventional levels, meeting high-speed flying camera requirements.

Application Case: Dual Perspectives of Industry and Research

- Industrial Quality Inspection Applications: In tire character recognition, four-zone lighting captures independent images from four directions. Combined with photometric stereo algorithms, it generates high-contrast images, resolving the blurring issues inherent in traditional ring lighting systems. In bearing pit detection, zoned illumination converts micron-level surface irregularities into 2.5D visual images, significantly enhancing algorithmic recognition accuracy.

- Scientific Observation Scenario: In biomedical research, a four-zone light source integrated with an autofocus system enables subcellular-level observation of organelle structures. For instance, during transparent sample analysis, adjusting the color temperature and brightness of each zone reduces light scattering interference, thereby enhancing the imaging signal-to-noise ratio.

- Special Material Inspection: For highly reflective materials such as metals and glass, the four-zone light source simulates polarized light effects through adjustable zone angles, minimizing glare interference. In semiconductor wafer inspection, this technology achieves seamless illumination at magnifications ranging from 0.7x to 4.5x, ensuring even the smallest defects are fully exposed.

The POMEAS Motorized Zoom Autofocus Microscope deeply integrates a four-zone light source with a motorized zoom lens and autofocus system. Users can adjust magnification from 0.7x to 4.5x with a mouse scroll wheel, paired with one-touch autofocus for an “instant clarity” observation experience. The independent adjustability of the four-zone illumination system adapts to diverse requirements, from standardized production lines to research-grade precision observation. For instance, during wafer tray inspection, the four-zone illumination ensures uniform illumination across every corner, working with the autofocus system to precisely capture micron-level defects.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com