Application of Telecentric Measurement System in the Measurement of 2mm Hardware Components

Testing Requirements

1. Measurement Object: Metal components measuring only 2mm in size, classified as micro-miniature metal workpieces. Traditional contact measurement methods are prone to operational errors that compromise results.

2. Accuracy Requirement: Must achieve 0.005mm precision, imposing stringent standards on measurement equipment accuracy control. Conventional low-cost measurement tools fall short of meeting this demand.

3. Scenario Constraints: Excludes flash gauges (due to complex equipment structure unsuitable for convenient measurement of small parts). Requires support for inline measurement with seamless integration into production lines to avoid efficiency losses caused by offline measurement.

Solution: Telecentric Measurement System HM-1040

1. Compact and easily integrated into production lines: The equipment features a compact design that requires minimal production space. It can be directly embedded into existing production line inspection stations, enabling seamless “production-measurement” integration. This eliminates the need for manual part transfer and prevents secondary positioning errors.

2. Ultra-high precision meeting stringent standards: Measurement accuracy reaches 1μm (0.001mm), far exceeding the customer's 0.005mm requirement. It reliably captures minute features on 2mm hardware components (e.g., 0.1mm hole diameters, 0.05mm wall thicknesses), ensuring dependable measurement results.

3. High-speed measurement aligned with production line cycles: A single measurement takes only 35ms, matching the part conveyance speed of high-speed production lines (e.g., hundreds of parts per minute). This prevents production line stagnation and safeguards manufacturing efficiency.

4. Customized lighting eliminates metal glare: An integrated green LED light source suppresses intense reflections on metal surfaces using specific wavelengths while enhancing part contours and feature boundaries. This produces clear, spot-free, shadow-free images, providing a high-quality foundation for precise measurement.

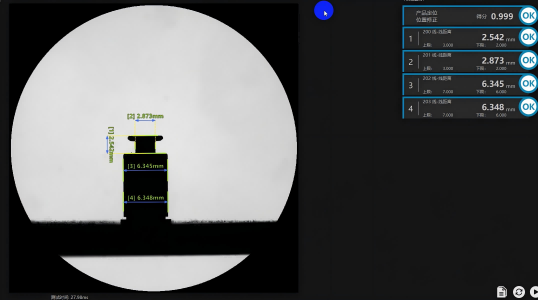

Test Results Display

Scenarios Where the Solution Applies

- Electronic components: micro connectors, chip leads, inductor coil dimension measurement

- Precision hardware: measurement of diameter, length and pitch for miniature screws, rivets and springs

- Medical components: microcatheters, outer diameter, wall thickness, and concentricity measurement of needles

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION