Full-Dimension Precision Measurement Solution for Cylinder Connectors

In the high-end equipment manufacturing sector, even the slightest error can trigger a chain reaction. As the pivotal components of pneumatic systems, the machining precision of cylinder connectors directly impacts equipment operational stability and service life. Traditional inspection methods, constrained by the randomness of manual operation and the physical limitations of tools themselves, struggle to meet modern industry's pursuit of “zero defects.” POMEAS leverages machine vision technology to introduce a full-dimension precision measurement solution specifically engineered for cylinder connectors. By deeply integrating optical imaging, artificial intelligence algorithms, and automated control, it sets a new benchmark for quality control in manufacturing.

I. Breaking Through Traditional Testing Challenges to Rebuild Quality Defenses

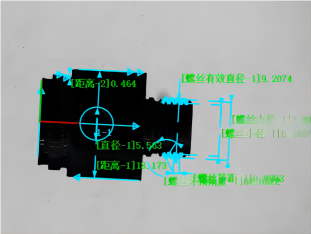

The production environment for cylinder connectors is fraught with challenges: complex geometries feature multiple sets of irregular holes, precision threads, and curved transitions, while customer tolerance requirements often reach micrometer levels. In the past, quality inspectors had to manually compare each component using tools like microscopes and dial indicators. This process was not only inefficient but also prone to missed defects or misjudgments due to fatigue. More critically, certain hidden flaws—such as internal burrs or minor deformations—were virtually impossible to detect through conventional methods.

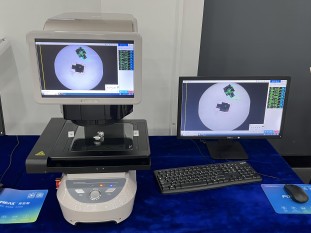

The POMEAS solution combines high-speed industrial cameras with custom ring lights to instantly capture the complete 3D profile of workpieces. Paired with proprietary edge detection algorithms, it automatically locates dozens of critical feature points, covering core parameters such as aperture size, groove width, thread profile angle, and surface roughness. The entire process requires no manual intervention, completely eliminating fluctuations caused by human factors.

II. Advantages and Applications of the Solution

1. Non-contact measurement safeguards delicate details: Utilizing telecentric optical lenses and a parallel backlight system, it achieves precise imaging without pressure—even on easily deformed materials like thin-walled aluminum alloys. For thread conditions inside deep holes, the system employs multi-angle oblique light sources to illuminate shadowed areas, ensuring every thread profile is fully captured within the inspection scope.

2. Dynamic tolerance calibration, intelligently adapting to process fluctuations: Unlike traditional fixed-threshold inspection methods, the POMEAS system incorporates an adaptive learning module. It continuously collects data from qualified products on the production line, dynamically adjusting tolerance ranges. This rigorously filters out genuine defects while preventing excessive rejection caused by normal variations like machine thermal drift. This “elastic” judgment mechanism significantly improves the balance between yield and production efficiency.

3. In-Depth Defect Analysis, Driving Process Evolution: Upon detecting anomalies, the system not only marks the location coordinates but also analyzes defect types through image comparison—is it a burr left from cutting? Or a microcrack caused by heat treatment? These diagnostic results are fed back to the production end in real time, helping engineers quickly pinpoint issues like tool wear or fixture loosening. This forms a quality closed-loop of “inspection-analysis-improvement.”

III. Plan Outcomes

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com