Comprehensive Applications of Machine Vision in the Die-Cutting Industry

I. Why Does the Die-Cutting Industry Need Machine Vision?

1. High precision requirements: Tolerances for die-cut products (e.g., flexible screen glass covers, precision labels) often need to be controlled within ±0.1mm, which is difficult for the human eye to achieve;

2. High consistency demands: In mass production, manual visual inspection is prone to fatigue, leading to missed defects or misjudgments;

3. Complex Process Challenges: When cutting multi-layer materials, hidden defects like burrs, misalignment, and bubbles frequently occur;

4. Cost Reduction and Efficiency Imperative: Replacing manual full inspection to reduce rework rates;

5. Data Traceability Pressure: Mandatory recording of quality data throughout the production process, particularly in industries like automotive and medical.

II. Four Core Application Scenarios

Die-cutting technology is widely applied across multiple industries including electronics, packaging, automotive, and medical fields, involving diverse materials such as paper, film, and metal foil. In these complex production processes, even minor errors can lead to significant quality issues.

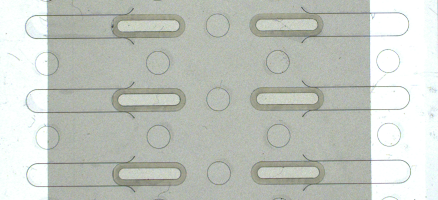

1. Material Feeding Positioning Compensation: Line scan cameras and red auxiliary positioning lasers rapidly locate substrate coordinates via mark points/QR codes/product contours. They calculate deviations between actual and theoretical positions, feeding this data to motion platforms for real-time adjustments.

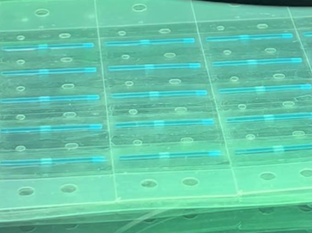

2. In-Process Die-Cutting Inspection: Pixel calibration and sub-pixel edge detection measure circular hole diameter deviations.

3. Final Inspection and Grading of Finished Products: Combines color recognition (distinguishing light/dark shades), 3D point cloud reconstruction (measuring curved surface radii), and near-infrared transmission (detecting internal bubbles). Rejects are automatically marked and diverted to the scrap bin, while acceptable products are graded and packaged accordingly;

4. Equipment Condition Monitoring: Periodically captures images of the die-cutting blade's side surface, using texture analysis to predict replacement cycles.

Machine vision is reshaping the die-cutting industry's quality control system, shifting from “post-production sorting” to “pre-emptive prevention + in-process control.” Enterprises are advised to follow a “point-to-surface, easy-to-difficult” implementation path: prioritize piloting in highest-value processes (e.g., positioning compensation before blanking), then gradually expand across the entire chain after accumulating successful cases.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION