Delving into the High-Precision Optics and AI Algorithms Behind the ‘Image Measuring Instrument’!

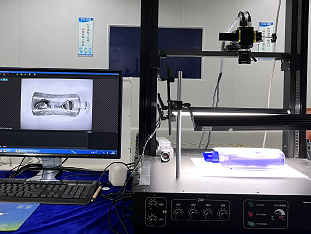

In the fields of precision manufacturing and quality inspection, image measurement instruments have long transcended the traditional role of ‘photographic documentation,’ evolving into intelligent inspection platforms that integrate high-precision optical systems with AI algorithms. The POMEAS Image3 series measurement equipment epitomizes this technological advancement, with its micron-level measurement accuracy underpinned by the deep synergy between optical engineering and artificial intelligence.

I. Optical Systems: The Revolution from “Lenses” to “Optical Correctors”

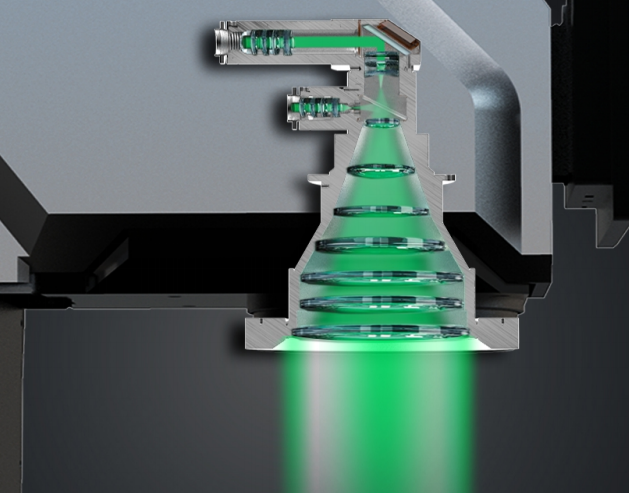

1. Dual-Axis Optical System: The “Optical Correction Glasses” That Eliminate Parallax

Traditional lenses are prone to measurement errors due to parallax issues. The Image3 series employs a dual telecentric optical system that eliminates parallax interference entirely through a design where both the object-side and image-side principal rays are parallel to the optical axis. Experimental data shows that within a temperature fluctuation range of 20°C to 40°C, its measurement repeatability error remains consistently controlled within ±0.5μm. This characteristic enables it to reliably capture product dimensional changes on automated production lines.

2. High-resolution lens: 20-megapixel “pixel-level” detail reproduction

The Image3 series features a 20-megapixel high-definition industrial camera, doubling the pixel density compared to traditional models. Taking the φ25mm high-precision camera as an example, its pixel equivalent can reach as low as 0.0001mm, enabling precise capture of minute features such as burrs and steps at the 0.01mm level. More crucially, its pixel size is highly matched to the lens's optical resolution, eliminating the resource waste caused by pairing “high-pixel cameras with low-resolution lenses.” This ensures every pixel carries meaningful information.

3. Seamless Dual-Camera Switching: A “Two-in-One” Solution Combining Wide Field of View and High Precision

To address the challenge of inspecting both overall dimensions and precision features on large components, the Image3 series innovatively employs a dual-camera configuration: a φ100mm wide-field camera paired with a φ25mm high-precision camera. The wide-field camera covers square parts with 50mm sides in a single scan, rapidly screening for surface defects. The high-precision camera magnifies 0.5mm apertures to full screen, measuring minute features like roundness error and edge perpendicularity. Both cameras' coordinate systems are pre-calibrated, eliminating the need for recalibration during switching and preventing positioning errors caused by manual adjustments.

II. AI Algorithms: The Leap from “Image Processing” to “Intelligent Decision-Making”

1. Adaptive Edge Detection Algorithm: An Intelligent Boundary Identifier Resistant to Interference

The traditional Canny edge detector is susceptible to noise interference. In contrast, the Image3 series employs a quadratic spline wavelet edge detection algorithm that achieves a balance between noise resistance and positioning accuracy through multi-scale analysis. During chip pin pitch measurement, this algorithm precisely measures pin widths and pitches to the 0.5mm standard, even identifying deviations in pin flatness to ensure compliance with industry standards.

2. Stereo Matching and 3D Reconstruction: From “Planar Projection” to “Spatial Modeling”

For complex structures such as mold cavities and curved parts, the Image3 series integrates binocular 3D measurement technology with an enhanced keypoint selection method to improve stereoscopic matching accuracy. Its 3D topography measurement capability evaluates panel thickness and surface variations. For instance, in smartphone panel inspection, it not only captures color deviations and shape errors but also reconstructs the true geometry of mold cavities, enabling users to promptly identify issues like wear and deformation.

3. Dynamic Compensation Algorithm: Real-time correction “Intelligent Error Correction System”

On automated production lines, factors such as environmental temperature fluctuations and equipment vibration may cause measurement errors. The Image3 series features a high-speed image processing system capable of continuous measurement at tens of frames per second, coupled with dynamic compensation algorithms to correct data in real time.

III. System Integration: From “Single Tools” to “End-to-End Solutions”

1. Hardware-Software Co-Optimization

The Image3 series incorporates software compatibility considerations during the hardware design phase. Its 20-megapixel camera undergoes rigorous lens compatibility verification to ensure the lens's imaging capabilities are fully realized.

2. Scenario-Based Design

From chip pin inspection in the electronics industry to bolt hole position measurement in aerospace components, the Image3 series adapts to diverse scenarios through its modular design.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com