Telecentric Measurement System enables 100% full inspection on production lines!

In traditional manufacturing processes, sampling inspection is like opening a blind box—you test a small sample and extrapolate the quality of the entire batch. This approach is fraught with uncertainty and risk: defective products that slip through undetected may quietly enter the market, leading to customer complaints, damage to brand reputation, and even massive recall costs. You can never be certain whether the next “blind box” hides a hidden hazard.

Potential Risks of Sampling Inspection:

1. Overgeneralization: It cannot guarantee that non-inspected products are 100% compliant.

2. Delayed Risk Detection: Quality issues are often discovered only after products have been released, by which time it is too late.

3. Reliance on Manual Labor: Prone to instability due to factors like operator fatigue and experience.

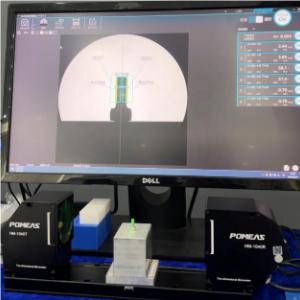

POMEAS Telecentric Measurement System HM Series

POMEAS Vision understands that “zero defects” is the core competitiveness of modern manufacturing. The HM Series Telecentric Measurement Systems leverage cutting-edge optical vision technology to transform your production line from passive “sampling inspection” to proactive “100% full inspection,” equipping quality control with an all-seeing “eagle eye.”

Core Advantages of the HM Series:

-

100% Full Inspection, Eliminating Defective Products: Say goodbye to sampling. Every product passing through each workstation undergoes high-speed, high-precision dimensional and visual inspection. Only products that meet 100% compliance with standards are allowed to proceed to the next stage, fundamentally achieving “zero” defective products released.

-

Millisecond-level detection combines speed with precision: Utilizing advanced image processing algorithms, it completes multiple dimensional measurements (such as length, diameter, angle, and contour) for individual products within milliseconds. This fully aligns with the production rhythm of high-speed assembly lines, ensuring no slowdown in manufacturing efficiency.

-

Non-contact measurement ensures non-destructive and reliable results: Optical measurement methods eliminate contact with product surfaces, enabling precise inspection of both delicate components and high-temperature products without damage—safely and reliably.

-

Data-Driven, Empowering Smart Manufacturing: Generate and record inspection data for every product in real time, enabling effortless statistical analysis. Not only does it provide real-time alerts, but it also delivers robust data support for process optimization and quality traceability, driving enterprise digital transformation.

Case Study:

Install the HM series Telecentric Measurement System above the production line conveyor belt, equipped with a dedicated lighting system. As each screw passes through the inspection station, the camera captures a rapid image. The system instantly completes image analysis and compares it against preset tolerance ranges.

Achieves 100% inspection: Processes thousands of screws per minute with zero omissions. Zero defects released: Any screws exceeding dimensional tolerances are immediately flagged by the system and automatically removed by downstream rejection mechanisms, ensuring defective parts are firmly blocked on the production line. Enhanced efficiency: Replaces multiple quality inspectors, boosting inspection efficiency by over 300% while generating comprehensive quality reports.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com