SFS-D8080K Spectral Confocal Sensor for Electrode Sheet Thickness Measurement

I. Industry Pain Points and Transformation Needs

In the current era of rapid growth in the new energy industry, lithium batteries serve as the core power source. The thickness uniformity of their internal electrode sheets directly impacts the battery's energy density, cycle life, and safety performance. Traditional contact-type thickness gauges not only pose a risk of scratching but also fail to meet the dynamic inspection requirements of high-speed production lines. The market urgently requires a high-precision, non-contact online measurement solution. The SFS-D8080K spectral confocal sensor, independently developed by POMEAS, is precisely the innovative tool designed for this purpose.

II. Technological Breakthrough: A New Benchmark in Optical Precision Measurement

1. Confocal Spectral Analysis Technology

Utilizing advanced white light interferometry principles, this technology employs a multi-wavelength composite light source incident perpendicular to the measured surface. It achieves sub-micron resolution by analyzing interference fringes generated from path differences across different wavelengths. Compared to traditional laser triangulation methods, this approach remains unaffected by material reflectivity, demonstrating superior adaptability for complex scenarios such as metal foils and coated composite structures.

2. Intelligent Algorithm Optimization

The built-in high-speed FPGA chip, combined with adaptive filtering algorithms, eliminates environmental vibration interference in real time, ensuring repeatable measurement accuracy of ±0.1μm even during high-speed equipment operation. A unique temperature compensation system effectively addresses cumulative errors caused by thermal expansion.

III. Comprehensive Analysis of Product Advantages

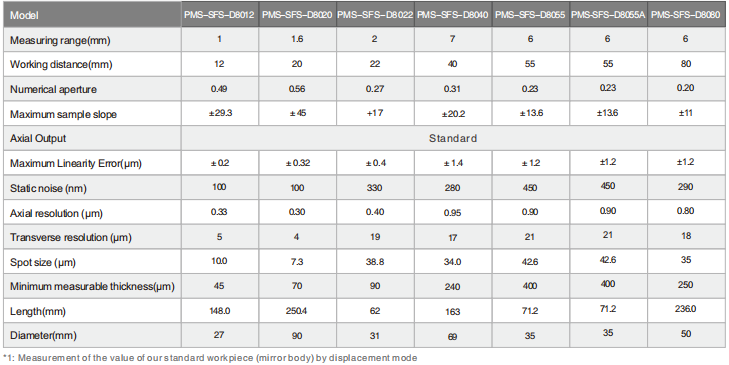

1. Outstanding Performance Parameters

2. Innovative Design Highlights

• Modular optical probe: Enables rapid interchangeability of lenses with different field-of-view angles, accommodating both detailed local inspection and full-width scanning.

• Dual-channel independent calibration: Supports simultaneous measurement of upper and lower surfaces, automatically calculates total thickness and single-side deviation;

• Self-cleaning function: The pneumatic dust removal device effectively prevents dust buildup, reducing the frequency of manual maintenance.

IV. Smart Manufacturing Empowerment: From Data Acquisition to Process Control

The complementary PMS intelligent management system is deeply integrated with the MES platform, delivering three core benefits:

-

Visual Monitoring Interface: Real-time display of 3D morphology cloud maps and thickness distribution heatmaps, with automatic marking and traceability of anomaly points.

-

SPC Statistical Analysis Module: Automatically generates CPK/PPK process capability indices and issues early warnings for potential process deviations.

-

Closed-loop feedback mechanism: Interoperates with the coating machine to achieve millisecond-level correction response for thickness deviations.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com