What is the difference between a “fisheye lens” and a “360° lens”?

In the field of industrial inspection, “fisheye lenses” and “360° lenses” are often confused, yet they exhibit fundamental differences in optical design, imaging principles, and application scenarios. Industrial 360° lenses are not merely fisheye lenses with an enlarged field of view. Instead, they achieve high linearity and low distortion imaging within a circular field of view through the coordinated operation of precision optical systems and algorithms, meeting the stringent demands of precision inspection.

I. Optical Structure

Fisheye lenses employ a reverse telephoto objective structure, featuring a first lens element that protrudes in a parabolic shape. By introducing pronounced barrel distortion to compress vast spatial areas, they achieve ultra-wide-angle imaging spanning 180° to 270°. For example, a certain fisheye lens model exhibits up to 300% stretching distortion at the image edges within an 180° field of view, causing straight lines to curve. This limits its application to scenarios with high tolerance for distortion, such as panoramic surveillance or artistic photography.

Industrial 360° lenses employ a multi-element compound design. By optimizing lens curvature, material refractive index, and focal power distribution, they achieve near-zero distortion imaging across a 360° circular field of view. Take a certain brand's 360° internal wall inspection lens as an example. Its optical system incorporates 12 aspherical lenses. By precisely controlling light propagation paths, linearity errors at the image edges are maintained below 0.1%, ensuring accurate detection of defects such as threads and scratches on the inner walls of cylindrical objects.

II. Imaging Principle

Fish-eye lenses operate on the principle of “non-similar imaging.” Their imaging models—such as equidistant projection and stereoscopic projection—compress the hemispherical object surface into a plane through mathematical transformations, yet no linear correspondence exists between the object and image. For instance, in the equidistant projection model, a single pixel at the image edge may correspond to several millimeters of deformation in the actual object, resulting in dimensional measurement errors exceeding 10%.

Industrial 360° lenses pursue “geometric fidelity,” achieved through the following technologies:

- Optical Correction: Employing a dual-bonded lens assembly to correct chromatic aberration, while utilizing mutually spaced thin lens groups to eliminate field curvature, ensuring aberrations across the entire field of view remain within the diffraction limit.

- Algorithmic Compensation: Combining camera intrinsic parameters (focal length, principal point coordinates) and extrinsic parameters (rotation matrix, translation vector), inverse projection transformation restores distorted images to true geometric shapes. For example, a 360° bottle cap detection system uses calibration algorithms to restore circular bottle caps at image edges to their actual diameters, achieving measurement errors below 0.05mm.

- Resolution Optimization: Uniformly distributes pixel density across the 360° circular field of view to eliminate resolution disparities between center and periphery. For instance, a 4K-resolution 360° lens allocates approximately 12 pixels per degree within its 360° horizontal and 180° vertical fields of view, ensuring precise capture of minute defects (e.g., 0.1mm scratches).

III. Application Scenarios

1. Due to their strong distortion characteristics, fisheye lenses are primarily used for:

- Security Surveillance: A single fisheye lens can cover large areas (such as shopping malls or parking lots), but requires software stitching to achieve panoramic monitoring. Objects at the image edges are difficult to identify.

- Virtual Reality: Used to generate immersive panoramic videos, but requires post-processing to eliminate distortion and cannot be directly used for dimensional measurement.

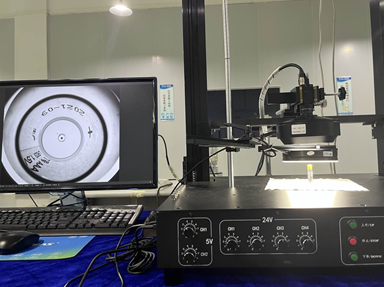

2. Industrial 360° lenses focus on high-precision inspection, with typical applications including:

- Inner Wall Inspection of Cylindrical Objects: For applications such as metal pipes, rifling in artillery shells, and corrosion defect detection, the lens must penetrate confined spaces while providing clear imaging of the entire inner surface.

- Cap/Can Quality Inspection: Utilizes 360° imaging to detect sealing lines and printing defects, eliminating missed inspections caused by blind spots.

IV. Performance Comparison

1. Field of View: Fisheye lenses typically offer a field of view ranging from 180° to 270°, covering nearly hemispherical spatial areas. However, constrained by their optical structure, their imaging area is circular with noticeable distortion at the edges. Industrial 360° lenses achieve seamless 360° coverage through a ring-shaped field of view design, producing a cylindrical imaging area that fully captures the entirety of cylindrical or ring-shaped objects.

2. Distortion Rate: Distortion is a key metric for evaluating a lens's imaging fidelity. Fisheye lenses intentionally introduce strong barrel distortion to compress space, with edge image stretching exceeding 300%. This distorts straight lines into curves, rendering them unsuitable for dimensional measurement. Industrial 360° lenses, however, utilize multi-lens group optimization and algorithmic compensation to control distortion within 0.1% across the entire field of view. This ensures consistent geometric relationships between image edges and centers, meeting precision inspection requirements.

3. Resolution Uniformity: Fisheye lenses exhibit a “high center, low edge” resolution distribution. While the central region boasts high pixel density for detailed imaging, the peripheral area suffers significantly reduced pixel density due to excessive light refraction angles, resulting in detail loss. Industrial 360° lenses achieve uniform resolution across the entire 360° circular field of view by evenly distributing pixel density. For example, a 4K resolution lens corresponds to approximately 12 pixels per degree of field of view, ensuring even minute defects (such as 0.1mm scratches) from center to edge are clearly captured.

4. Dimensional Measurement Accuracy: Due to severe distortion, fisheye lenses cannot be directly used for dimensional measurement. Complex algorithms are required to restore distorted images to true geometric shapes, but reconstruction errors typically exceed 10%. Industrial 360° lenses, however, achieve direct dimensional measurement through high-linearity imaging and calibration algorithms. For instance, in bottle cap inspection, measurement errors can be controlled within 0.05mm, meeting industrial-grade precision requirements.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com