Batch Inspection Solution for Online Projectors in the Precision Electronics and Connector Industry

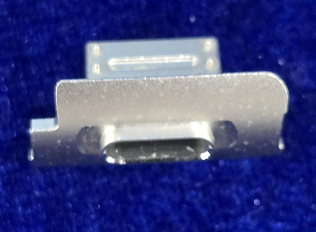

In the precision electronics and connector manufacturing sector, dimensional accuracy of micro-components directly determines product performance and reliability. Take the Type-C interface in mobile phone components as an example: contact pitch tolerance must be controlled within ±0.05mm, while hole diameter tolerance must be less than 0.02mm. Traditional contact-based measurement tools often scratch workpiece surfaces, and individual part inspection takes over 5 minutes—failing to meet the efficiency demands of mass production. Online projectors, leveraging optical non-contact measurement technology combined with intelligent software algorithms, are redefining industry standards for batch inspection of micro-components.

I. Technological Breakthroughs in Optical Non-Contact Measurement

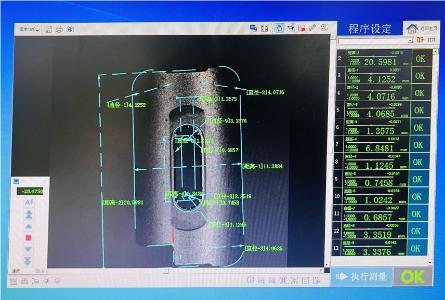

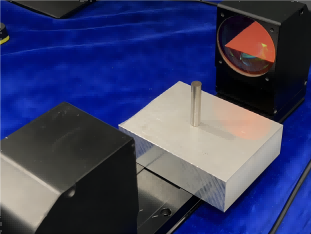

The core principle of an online projector involves magnifying workpiece contours onto a projection screen via high-magnification optical lenses, combined with a CCD image sensor to achieve digital imaging. Taking the POMEAS online projection dimension measuring instrument as an example, its imaging clarity surpasses traditional equipment by 30%, enabling clear capture of minute features down to the 0.1mm level. When inspecting mobile phone SIM card holders, the system projects the product outline and measures dimensions within 35 milliseconds. It fully reveals chamfer details along the holder's edges, with repeatability error controlled within ±0.002mm.

The example of testing a Type-C port is shown in the figure above.

II. Intelligent Upgrades for Batch Inspection

The intelligent upgrade of online projectors manifests in three dimensions:

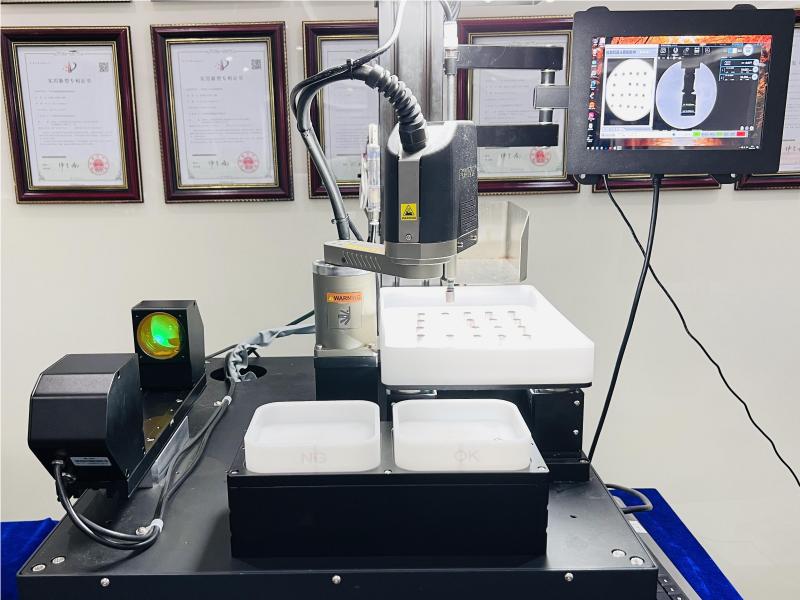

1. Automated Process Design: Integrates robotic arms via PLC control systems to achieve automatic workpiece loading and unloading.

2. Multi-Parameter Synchronous Measurement: Supports multi-dimensional data acquisition tailored to the complex structures found in the connector industry.

3. AI-Assisted Defect Detection: Incorporates deep learning algorithms enabling automatic identification of surface defects such as scratches and burrs.

POMEAS online projectors leverage optical dimensional measurement and contour measurement technologies to solve efficiency and precision challenges in mass inspection of micro-components. From mobile phone parts to high-end connectors, and from consumer electronics to industrial manufacturing, this technology is redefining precision manufacturing quality standards with millimeter-level accuracy and intelligent capabilities.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION