In the beverage and pharmaceutical packaging sectors, the ultimate solution for bottle and can inspection is achieving breakthrough innovation through 360° lens technology. This technology simultaneously captures three core metrics—label printing, cap sealing integrity, and thread integrity—at a single station. It condenses the traditional multi-station sequential inspection process into parallel processing at a single station, boosting inspection efficiency by over 300% while maintaining a false rejection rate below 0.1%.

I. Technical Principle: Industrial-Grade Breakthrough in 360° Dead-Angle-Free Imaging

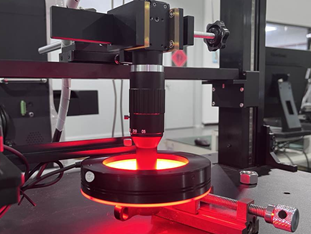

Traditional inspection solutions rely on multiple cameras capturing images in separate zones, suffering from issues such as image stitching errors, high equipment costs, and slow inspection speeds. In contrast, the 360° lens employs a refractive-reflective optical system that uses curved mirrors to refract light from the surface of bottles and cans onto the imaging chip, forming a circular panoramic image. For instance, the POMEAS 360° external lens captures the entire outer circumference of objects ranging from 7.5 to 30mm in diameter and 5.3 to 25mm in height in a single pass. In beverage bottle inspection, a single frame covers the full circumference of the label, the bottle neck surface, and the thread profile.

This technology achieves three core detections through sub-pixel level image processing algorithms:

- Label Printing Inspection: Utilizes machine vision to compare label designs with actual printed images, identifying defects such as misalignment, color deviation, and missing text.

- Cap Seal Integrity Inspection: Combines pressure sensor data with cap edge image analysis to assess seal ring integrity.

- Thread Integrity Inspection: Captures thread profiles using high-frequency flash illumination and high-speed cameras to detect defects like broken teeth, burrs, and deformation.

II. Application Scenarios: A Quality Inspection Revolution in Beverage and Pharmaceutical Packaging

1. Beverage Industry: Full Process Optimization from Filling to Labeling

In beer filling production lines, 360° cameras can be integrated into multi-station intelligent inspection devices to simultaneously perform the following inspections:

- Label Positioning Accuracy: Sub-pixel analysis of label edges via multi-angle vision stations, with misalignment tolerance below 0.3mm;

- Cap Sealing Integrity: Ultrasonic sensors detect cap shape integrity, combined with image analysis of sealing pressure distribution;

- Thread Integrity: At the cap inspection station, top and side cameras jointly capture thread trajectories to identify foreign object contamination or batch errors.

2. Pharmaceutical Industry: Sterile Packaging Solutions Compliant with GMP Standards

In the medicine bottle filling scenario, the 360° camera focuses on detecting:

- Bottle Neck Flatness: Measures deviation in bottle neck roundness via laser distance sensors to ensure proper sealing with caps;

- Thread Cleanliness: Captures minute impurities on thread inner walls using high-resolution cameras to prevent drug contamination;

- Label Compliance: Identifies critical information like drug batch numbers and expiration dates through OCR technology to prevent label mix-ups.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com