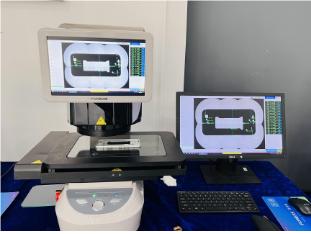

Image Dimension Measuring Instrument for Mobile Phone Mid-Frame Mold Measurement

In the field of mobile phone manufacturing, the precision of mid-frame molds directly determines the assembly quality and overall performance of the phone's mid-frame. Traditional measurement methods have gradually revealed shortcomings such as low efficiency and limited accuracy when addressing the complex structures and high precision requirements of mobile phone mid-frame molds. Image dimension measuring instruments, with their advantages of high precision and rapid measurement, have become the ideal tool for measuring mobile phone mid-frame molds, providing strong support for the high-quality development of mobile phone manufacturing.

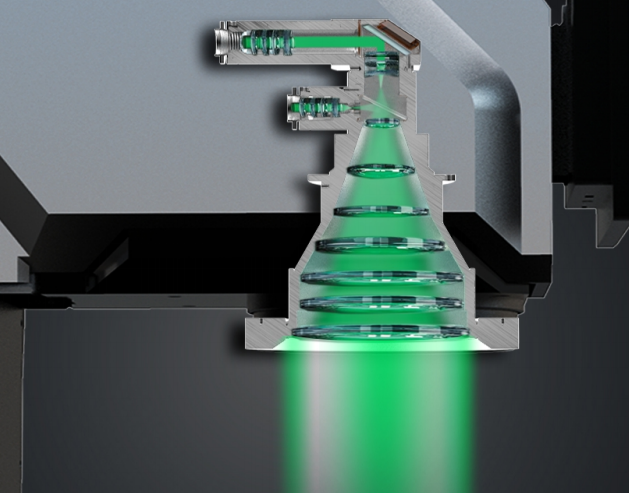

Working Principle of an Image Dimension Measuring Instrument

The image dimension measuring instrument primarily consists of a high-precision camera, a precision optical system, and advanced software algorithms. The high-precision camera serves as the “eyes” of the device, capturing clear and detailed image information of the mold surface; The precision optical system ensures image quality, laying the foundation for subsequent accurate measurements; the software algorithms serve as the core “brain” of the entire measurement process, employing complex image processing techniques to analyze and compute the acquired images. Through the coordinated operation of these components, the measuring instrument converts the mold's two-dimensional or three-dimensional images into precise dimensional data, enabling accurate measurement of critical mold dimensions and shapes.

Specific Application of Image Dimension Measuring Instruments in Mobile Phone Mid-Frame Mold Measurement

1. Critical Dimension Measurement

The mid-frame mold for mobile phones contains numerous critical dimensions, such as length, width, height, aperture size, and slot width. Taking the keyhole on the mid-frame as an example, its aperture size and positioning accuracy directly impact the installation and tactile feedback of the keys. Image dimension measurement systems rapidly capture images of keyhole openings. Through software algorithms, they precisely calculate the actual aperture dimensions and the positional coordinates of the hole center relative to the mold edge. Compared to traditional measurement tools, this method not only significantly accelerates measurement speed but also achieves measurement accuracy as high as 1.5μm. This effectively prevents issues like difficult button installation or loosening caused by dimensional deviations.

2. Shape Measurement

Smartphone mid-frame molds feature complex shapes encompassing various curves, arcs, and irregular structures. For instance, mid-frame edges typically employ rounded corner transitions where radius precision critically impacts aesthetic appeal and grip comfort. The image dimension measuring instrument precisely measures these rounded corners by analyzing contour curves in captured images to accurately calculate radius values. Additionally, for irregular structures on the frame—such as camera cutouts and fingerprint sensor mounting slots—the measuring instrument can precisely outline their shapes, ensuring mold manufacturing meets design specifications.

3. Surface Defect Detection

Beyond dimensional and shape measurement, image dimension measuring instruments can detect surface defects on smartphone midframe molds. During mold manufacturing, defects like scratches, pits, or bubbles may arise due to various factors. These imperfections not only compromise the mold's appearance but can also impact its service life and product quality. Through high-resolution image capture and analysis, the measuring instrument swiftly identifies minute surface defects, accurately measuring their dimensions and locations. This provides critical data for mold repair and quality control.

Advantages of Image Dimension Measurement Instruments

1. Efficiency

Traditional measurement methods, such as using calipers or micrometers, require point-by-point inspection of molds, making the process cumbersome and time-consuming. In contrast, the image dimension measuring instrument employs a non-contact measurement approach. Simply place the mold on the measurement platform, and the camera rapidly captures images. The software then swiftly completes the measurement and analysis of multiple dimensional and shape parameters of the mold, significantly enhancing measurement efficiency and shortening the mold inspection cycle. This helps accelerate the production progress of mobile phone mid-frames.

2. High Precision

As mentioned earlier, the image dimension measuring instrument achieves measurement accuracy as high as 1.5μm, meeting the stringent precision requirements for smartphone mid-frame molds. In the mobile manufacturing industry, even minor dimensional deviations can lead to assembly difficulties, performance degradation, or product scrap. High-precision measurement results provide reliable assurance for mold manufacturing and quality control, ensuring produced mid-frames comply with design standards and improving product yield rates.

3. Comprehensive Capability

The image dimension measuring instrument can simultaneously measure multiple dimensional and geometric parameters of a mold, enabling comprehensive mold inspection. Compared to traditional measuring tools that can only measure single parameters, it provides more comprehensive mold information. This helps engineers promptly identify comprehensive issues in the mold manufacturing process and offers more thorough data support for mold optimization and improvement.

4. Traceability

The instrument's software system meticulously records and stores measurement data, establishing a comprehensive measurement database. This data serves not only for analyzing current mold quality but also provides historical references for subsequent mold manufacturing, maintenance, and enhancements. Through data analysis, enterprises can distill lessons learned from mold production processes, continuously refine manufacturing techniques, and elevate both mold quality and production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com