In industrial vision inspection, camera selection directly determines inspection accuracy and efficiency. The choice between monochrome and color cameras is not solely determined by the need for “color information.” The core differences lie in fundamental technical parameters such as resolution, sensitivity, and signal-to-noise ratio, as well as functional adaptability across various application scenarios.

I. Technical Advantages of Monochrome Cameras: A Triple Edge in Resolution, Sensitivity, and Signal-to-Noise Ratio

1. Resolution: Higher pixel utilization efficiency

The sensor in a monochrome camera only needs to capture light intensity information (grayscale values), with each pixel independently recording brightness data without allocating resources to process color information. Therefore, at the same pixel size, monochrome cameras offer higher effective resolution. For example:

-

Theoretical Comparison: Color cameras employ a Bayer color filter array (where each pixel records only one of red, green, or blue, requiring interpolation algorithms to reconstruct full-color images), resulting in an effective resolution of only 1/3 to 1/2 of the nominal value. In contrast, monochrome cameras suffer no such loss and can fully utilize all pixels.

-

Practical Example: When inspecting circuit board traces with a width of 0.1mm, a monochrome camera (5 megapixel) can clearly distinguish the edges of the traces, whereas a color camera with the same resolution may produce misjudgments due to blurring caused by interpolation.

2. Sensitivity: Low-light “night vision capability”

Black-and-white cameras exhibit significantly greater sensitivity to light than color cameras, due to the following reasons:

-

No filter loss: The Bayer color filter array on color cameras blocks some light (the red filter only allows red light to pass through, while green and blue light are absorbed), resulting in approximately 60% less light entering the camera. Monochrome cameras lack color filters, allowing light intake to approach theoretical values.

-

Higher Quantum Efficiency: The quantum efficiency (the ratio of photons converted to electrons) of monochrome camera sensors (such as CCD or CMOS) is generally 10%–20% higher than that of color sensors across the visible spectrum, with a more pronounced advantage in the near-infrared band (e.g., 850nm).

-

Application Scenarios: In semiconductor packaging inspection, monochrome cameras can clearly capture pin solder joints under low-illumination conditions (<10 lux), whereas color cameras require additional lighting, increasing system complexity.

3. Signal-to-noise ratio: A natural barrier against noise

Signal-to-noise ratio (SNR) is a key indicator for measuring image quality. Monochrome cameras achieve higher SNR due to the following design features:

-

No color noise: Interpolation algorithms in color cameras introduce color artifacts (such as moiré patterns and false colors), particularly generating noise in edge regions. Monochrome cameras do not suffer from this issue, resulting in purer images.

-

Wider dynamic range: Monochrome camera sensors can be designed with higher full well capacity (the amount of electrons a single pixel can store), preventing overexposure in bright light and underexposure in low light. For example, an industrial-grade monochrome camera achieves a dynamic range of 70dB, while a comparable color camera only reaches 60dB.

-

Typical Case: In metal surface defect detection, monochrome cameras can clearly distinguish 0.01mm-level scratches from reflective noise, whereas color cameras may misinterpret defects due to color interference.

II. Irreplaceable Applications for Monochrome Cameras: Dimension Measurement and Character Recognition

1. Dimension Measurement: Sub-pixel Accuracy Depends on Grayscale Information

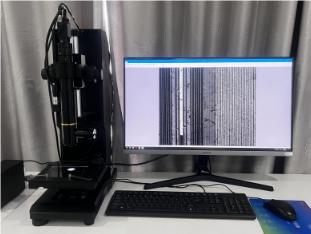

In precision manufacturing, dimension measurement requires micrometer-level accuracy (e.g., semiconductor wafer line widths, PCB aperture sizes). Monochrome cameras achieve this through the following technologies:

- Sub-pixel edge detection: Utilizes grayscale gradient information (e.g., Sobel operator, Canny operator) to locate edges with accuracy down to 0.1 pixels. For instance, a 5-megapixel monochrome camera paired with a 20x lens can achieve 1μm measurement precision.

- No color interference: Color edges in color cameras may obscure true geometric edges (e.g., the junction between a red pad and a green substrate), leading to measurement errors.

2. Optical Character Recognition (OCR): Gray-scale contrast is key.

In barcode, QR code, or printed character recognition, monochrome cameras enhance recognition rates through high-contrast grayscale images:

-

Contrast Advantage: In monochrome images, the grayscale difference between characters and background can exceed 200 levels (8-bit images), whereas color images may suffer from insufficient contrast due to similar colors (e.g., red characters on a green background).

-

Speed Advantage: Monochrome cameras process smaller data volumes without handling color information, achieving 30%–50% faster processing speeds than color cameras. This makes them ideal for high-speed production lines (e.g., inspecting 10,000 products per hour).

III. The Core Value of Color Cameras: The “Visual Code” for Color Discrimination and Defect Detection

1. Color Discrimination: From “Seeing” to “Understanding”

Color cameras restore objects' true colors through red, green, and blue (RGB) channel information, proving indispensable in the following scenarios:

- Color Matching: In textile and printed material inspection, determining whether colors meet standard color charts (e.g., ΔE<2). Monochrome cameras cannot distinguish color differences, while color cameras quantify color deviation values.

- Color Sorting: In fruit grading and pharmaceutical packaging inspection, products must be categorized by color (e.g., red apples vs. green apples). When combined with machine learning models, color cameras achieve classification accuracy exceeding 99%.

2. Defect Detection: Color Anomalies as Key Indicators

Many industrial defects manifest as color changes (e.g., oxidation, contamination, scorching). Color cameras directly capture these characteristics:

-

Metal oxidation detection: Oxidized aluminum surfaces exhibit rainbow-colored spots. Monochrome cameras detect only brightness changes, leading to missed defects. Color cameras identify abnormal reflections at specific wavelengths (e.g., 650nm red light).

-

Liquid impurity detection: On beverage filling lines, color cameras detect suspended impurities (e.g., black particles in transparent liquids) through color differences. Monochrome cameras may misinterpret these as background noise.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com