In precision manufacturing, 3D inspection, and intelligent equipment, “seeing clearly” and “measuring accurately” remain core requirements. Whether it's micro-positioning during chip packaging, flatness inspection of smartphone glass covers, or reference plane construction in 3D scanning, equipment must simultaneously deliver rapid focusing imaging and precise distance measurement. Traditional solutions often rely on two separate systems for focusing and distance measurement, which not only increases equipment size and cost but may also compromise efficiency due to coordination delays. The advent of laser autofocus sensors has broken this barrier—integrating “focusing” and “distance measurement” into a single unit, achieving the breakthrough of “dual outputs from a single detection.” The POMEAS LFS series laser autofocus sensor stands as a prime example of this technological approach.

I. Technical Core: The Common Logical Origin of “Focusing” and “Rangefinding”

To understand this “dual-nature” characteristic, we must first clarify the core principle of laser autofocus. Unlike traditional optical focusing, which relies on mechanical adjustments, laser autofocus sensors emit a highly stable laser beam onto the target object. An optical system then collects the reflected light signal. When the laser beam focuses on the object's surface, the reflected light forms a clear spot or interference fringes. The sensor's internal photosensitive element captures this signal, and through algorithms, rapidly determines the focal position to complete focusing. Crucially, the signals generated during this focusing process inherently contain precise distance information. The propagation time of the laser from emission to reflection back to the sensor, the displacement of the spot, or the pattern of interference fringes all directly correlate with the distance between the sensor and the target object.

Simply put, the essence of laser autofocus is determining the target's position by locating the “optimal focus point,” whose spatial coordinates precisely correspond to the distance between the sensor and the object's surface. This means that when an LFS series sensor completes rapid focusing, it outputs not only a “focus complete” control signal but also simultaneously outputs high-precision distance data. This data can represent either relative distance (e.g., height difference relative to the sensor's reference plane) or absolute distance (e.g., spatial coordinates relative to a preset zero point). Without requiring additional distance measurement modules, it truly achieves the functional synergy of “dual capabilities in one integrated unit.”

II. Dual Value Realization: Breakthroughs in Three Core Application Scenarios

This dual-functionality delivers revolutionary enhancements across numerous industrial applications. In Z-axis height measurement scenarios, traditional methods typically require focusing before distance measurement—a two-step process with inherent time lag that struggles to accommodate high-speed moving objects. In contrast, the POMEAS LFS series sensor outputs high-precision height data simultaneously with focusing, achieving microsecond-level response speeds. Whether detecting workpiece height on high-speed conveyor belts or measuring semiconductor wafer thickness, it enables “focus and measure instantly,” significantly boosting inspection efficiency.

The LFS series also demonstrates significant advantages in flatness inspection. Flatness testing requires precise height sampling at multiple points on an object's surface, followed by data fitting to determine compliance with flatness standards. Traditional solutions require separate focusing lenses and distance sensors, where calibration errors between the two systems compromise accuracy. The LFS series eliminates such inter-system errors through its integrated “focusing + distance measurement” design, achieving nanometer-level measurement precision. Its laser spot can be reduced to micrometer scale, enabling precise capture of minute surface irregularities. This makes it ideally suited for flatness inspection of high-end products like precision components and optical lenses.

In 3D scanning, establishing a reference plane is fundamental to ensuring scanning accuracy. Traditional 3D scanning requires separate distance measurement devices to determine the reference plane's position before initiating imaging, creating a cumbersome process where positioning errors propagate throughout the scan. The POMEAS LFS series sensor directly utilizes the distance data output during focusing as the reference plane parameter. It simultaneously performs focusing and supplementary distance sampling during scanning. This not only streamlines the scanning process but also ensures the reference plane and scanned imaging data originate from the same system. This significantly enhances the overall accuracy and data consistency of 3D scanning.

III. POMEAS LFS Series: Engineering Implementation of Technical Advantages

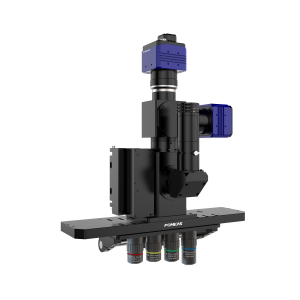

As a brand specializing in precision optical sensing technology, POMEAS has integrated years of optical design expertise into the development of its LFS series laser autofocus sensors. This series not only achieves the dual functionality of “focusing” and “distance measurement” in a single unit but also offers robust anti-interference capabilities, compatibility with diverse material surfaces (metal, glass, plastic, etc.), and broad environmental adaptability. Its output distance data can be directly integrated with motion control systems and data processing systems without requiring additional data conversion modules. This simplifies equipment integration, reducing R&D and manufacturing costs for end users.

From a technical perspective, the “focusing” and ‘ranging’ functions of laser autofocus sensors are inseparable twins, representing a deep exploration and innovative application of optical sensing principles. This breakthrough transcends the traditional mindset of “single-functionality,” elevating sensors from mere imaging tools to multifunctional detection cores. The POMEAS LFS series transforms this technological advantage into tangible application value through precise optical design and advanced algorithm optimization. It delivers more efficient, accurate, and integrated sensing solutions for precision manufacturing, intelligent inspection, and other fields.

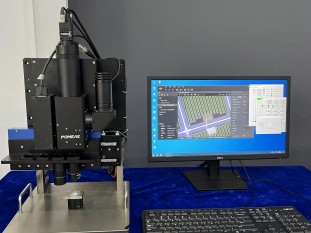

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com