Machine Vision vs Laser Scanning in Smartphone Case Inspection Applications

I. Background of Mobile Phone Case Dimension Inspection

With the growth of the 3C electronics industry, demand for phone cases has surged, and consumers now demand higher quality. Dimensional accuracy directly impacts compatibility and user experience. Phone case production features diverse categories and small batches. Traditional manual inspection is inefficient and prone to errors, making automated inspection solutions essential. Machine vision and line laser sensors are the mainstream choices.

II. Comparison of Two Mainstream Detection Methods and Their Advantages and Disadvantages

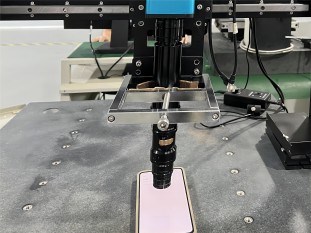

Machine vision solutions capture images using cameras and lighting systems, then extract dimensional features through algorithms for comparison against standards. Suitable for flat phone cases, they achieve 2D inspection accuracy of 0.01-0.05mm, with individual part inspection taking 0.5-2 seconds. Costs range from 30,000 to 100,000 yuan, but the system is sensitive to lighting conditions.

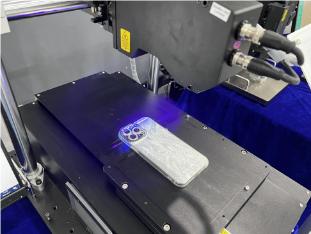

Line laser sensing solutions operate on the principle of triangulation, projecting laser lines to capture 3D coordinates and build models. They excel at inspecting complex curved surfaces with 3D accuracy ranging from 0.001 to 0.01 mm and strong resistance to light interference. However, inspection takes 2-5 seconds, costs between 100,000 and 300,000 yuan, and is sensitive to vibration.

Key differences are pronounced: - Accuracy: Machine vision excels at 2D inspection, while line lasers dominate 3D applications. - Efficiency: Machine vision is more efficient, suited for high-volume production. - Cost and environmental adaptability: Machine vision is lower-cost but environment-dependent; line lasers are higher-cost yet resistant to light interference.

III. POMEAS's Solution Advantages in the 3C Electronics Industry

POMEAS has deep expertise in the 3C electronics industry, offering significant solution advantages:

1. Customized design tailored to phone case characteristics and production capacity requirements, offering integrated inspection solutions;

2. Proprietary core technology ensuring 0.01mm-grade 2D and 0.001mm-grade 3D inspection accuracy;

3. High compatibility with existing assembly lines, supporting rapid changeovers and system integration;

4. Full lifecycle service including installation, commissioning, 24/7 technical support, and scheduled maintenance;

5. High cost-effectiveness achieved through R&D and supply chain optimization, helping businesses boost efficiency and reduce losses.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION