Lens Selection Guide | Navigation ZOOM Lenses and Dual-Telecentric Lenses

In the field of industrial vision inspection, double telecentric lenses and industrial navigation ZOOM LENS (such as the POMEAS series) represent two core optical devices, excelling respectively in ultra-high precision measurement and dynamic multi-scenario adaptation.

I. Technical Principles

1. Dual telecentric lens

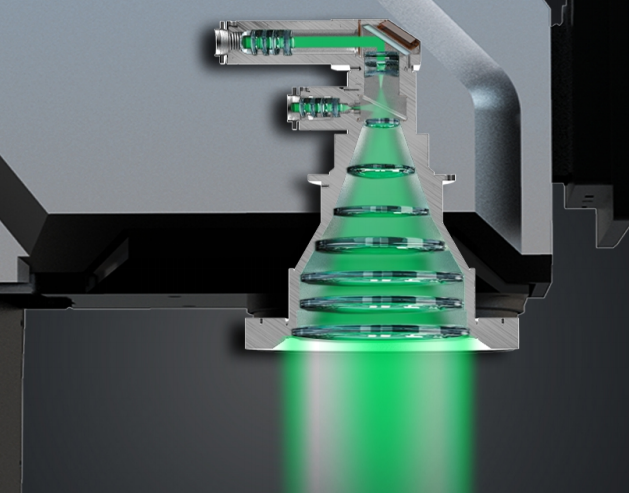

The dual telecentric lens employs a dual telecentric optical path design (where both incident and exit light rays are parallel to the optical axis), eliminating perspective distortion to achieve true “what you see is what you get” imaging. Its core advantages lie in:

- Ultra-low distortion (<0.02%): Ensures measurement errors <0.1μm for circular, square, and other geometric shapes, suitable for high-precision applications such as semiconductor pin pitch and precision mechanical clearances;

- Large Depth of Field (>10mm): Simultaneously captures axial dimensions of three-dimensional objects (e.g., springs, nuts), preventing missed inspections due to focal length variations;

- Fixed Magnification: Requires lens replacement based on object size (e.g., 0.5×, 1×, 2×), but maintains consistent magnification within the lens's depth of field range, delivering exceptional stability.

Typical Application: In semiconductor wafer inspection, dual telecentric lenses simultaneously capture pin pitch (0.01mm precision) and surface scratches (0.005mm width). Their parallel light characteristics effectively suppress image blur caused by conveyor belt vibration (±0.2mm).

2. Industrial Navigation ZOOM LENS

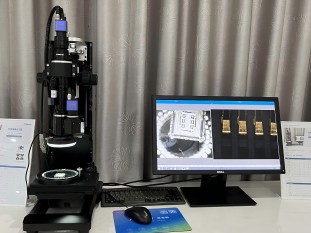

Industrial navigation ZOOM LENS achieve continuous focal length adjustment (e.g., 0.7-7.5×) through coordinated movement of multiple lens groups and motorized drive, integrating functions such as laser ranging, autofocus, and target tracking. Taking the POMEAS navigation lens LZ-650110-Z12 as an example:

- Dual-Field Synchronization: Supports simultaneous display of global field (low magnification, full-panel coverage) and detailed field (high magnification, defect focus), eliminating positioning errors caused by traditional lens switching;

- Main lens with small field of view for rapid precision measurement and observation;

- Navigation lens with large field of view (35.8mm x 26.9mm) for quick target acquisition;

- Superior optical performance: high resolution, low distortion, and ultra-high numerical aperture (N.A.) value;

- Compact structural design for easy integration and installation.

Typical Application: On automotive electronics assembly lines, POMEAS navigation lenses simultaneously display full-board layouts (field of view: 35.8mm x 26.9mm) and solder joint details (resolution: 0.005mm/pixel), boosting inspection efficiency by over threefold.

II. Performance Comparison: The Trade-off Between Precision and Flexibility

In terms of precision, dual telecentric lenses achieve sub-micron measurement accuracy (<0.1μm) thanks to their ultra-low distortion design, far surpassing the micron-level accuracy (<1μm) of industrial navigation ZOOM LENS, making them ideal for scenarios demanding extreme geometric shape and dimensional precision.

Examples include semiconductor manufacturing and precision machining. While industrial navigation ZOOM LENS offer slightly lower precision, their dynamic zoom capability (0.7x-7.5×) provides flexibility—covering multi-scale inspection needs from overall overviews to detailed close-ups without lens changes, significantly boosting inspection efficiency.

Regarding environmental adaptability, double telecentric lenses demand high stability in working environments, requiring vibration control (<0.01mm) to prevent image blurring. Thus, they are better suited for controlled settings like laboratories or precision machining workshops. In contrast, industrial navigation ZOOM LENS (such as the POMEAS Navigation Lens LZ-650110-Z12) demonstrates superior visual inspection capabilities—zooming from wide to narrow fields of view—through sealed designs and anti-shake algorithms, making it the preferred choice for component inspection.

III. Selection Guide: How to Match Requirements?

- Select dual telecentric lenses: Suitable for ultra-high precision measurement (e.g., semiconductor inspection), where the object size is fixed and high geometric fidelity is required, and the working environment is stable.

- Select industrial ZOOM LENS: Suitable for applications requiring frequent magnification switching (e.g., from full-board inspection to solder joint analysis).

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com