How does a point-spectrum confocal sensor achieve precise measurement of film thickness?

In the manufacturing of modern industrial products such as smartphone screens, automotive windshields, and OLED display panels, the precision of transparent material thickness control directly determines the product's optical performance and mechanical strength. Traditional contact measurement methods are prone to scratching material surfaces, while non-contact technologies like laser triangulation face the challenge of signal attenuation in transparent materials. Point-spectrum confocal sensors, leveraging their unique non-contact measurement principle, emerge as the “optical key” to solving the challenge of transparent material thickness measurement. Achieving sub-micron precision, they remain unaffected by material color, transparency, or surface texture.

I. The Core Technology of Point Spectral Confocal Sensors: Precision Scanning of the Light Cone

The core of the point-spectrum confocal sensor lies in its “light cone scanning” mechanism:

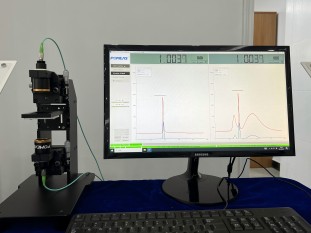

- Spectral Encoding Technology: White light is dispersed into a continuous spectrum via a dispersive element, with different wavelengths corresponding to distinct axial positions. For example, the POMEAS SFS-D8040 sensor utilizes a broad-spectrum light source spanning 405-650nm to achieve a 7mm measurement range.

- Confocal Focusing Principle: Reflected light intensity peaks only when the measured surface precisely aligns with the focal point of a specific wavelength. By detecting this peak wavelength, the system determines surface height with ±0.1μm accuracy.

- Multi-Layer Resolution Capability: For transparent materials, spectral peaks reflected from different interfaces form a “spectral fingerprint.” Algorithms separate these peaks to simultaneously determine the position of each layer's surface.

This technological principle inherently endows it with three major advantages:

- Material Universality: Measures any material—transparent, translucent, or colored—as long as optical interfaces exist.

- Interference Resistance: Surface roughness (Ra<1.6μm) and tilt angles (±20°) do not affect measurement results.

- Dynamic Response: 20kHz sampling frequency enables real-time tracking of thickness changes during high-speed motion.

II. Single-Side Measurement: Cracking the Thickness Code of Single-Layer Transparent Materials

For single-layer transparent materials (such as glass covers or resin lenses), point-spectral confocal sensors can calculate thickness through single-side measurement:

- Dual-Surface Positioning Method: The sensor simultaneously captures the reflected spectral peaks from both the upper and lower surfaces of the material. For example, when measuring 3mm-thick glass, the system detects two spectral peaks spaced approximately 3mm apart (accounting for refractive index correction).

- Refractive Index Compensation Algorithm: By inputting the material's refractive index (e.g., glass n=1.5), the system automatically corrects for optical path differences. The POMEAS SFS series sensors feature a built-in database of common materials, supporting rapid access to over 20 materials including glass, PC, and PMMA.

- Edge Detection Optimization: Employing a dynamic threshold algorithm to address refractive index variations at material edges ensures measurement stability. When measuring the edges of smartphone screen cover glass, edge measurement errors can be controlled within ±0.5μm.

III. Bilateral Synchronous Measurement: Peering into the Inner World of Multilayered Translucent Structures

For multi-layer transparent composites (such as OLED display modules and automotive window films), single-side measurement becomes ineffective due to overlapping signals from multiple reflections. In such cases, a dual-side simultaneous measurement approach must be employed:

1. Top-Bottom Sensor Pairing: A sensor is positioned on each surface of the material to collect data synchronously. For example, when measuring an OLED display module's encapsulation glass (0.5mm) + polarizer (0.2mm) + OLED layer (0.3mm) structure, the top and bottom sensors respectively locate the top and bottom surfaces.

2. Spectral Decoupling Technology: Separates overlapping spectral signals via Fourier transform. POMEAS' CCSVR1.0.2.4 software identifies interfaces across up to five transparent layers with interlayer resolution reaching 0.1μm.

3. Dynamic Calibration Mechanism: Phase-locking technology synchronizes upper and lower sensor data despite material bending or vibration. When measuring PVB interlayer thickness in automotive windshields, repeatability remains within ±0.3μm even with 0.5° glass tilt.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com