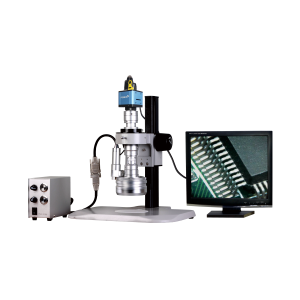

Application of 3D tool microscope for surface topography analysis of micro- and nanomaterials

In the semiconductor manufacturing process, 3D tool microscope can be used to detect tiny defects and contamination particles on the chip surface. By accurately measuring and analyzing its surface topography, problems in the manufacturing process can be detected and corrected in time, improving the quality and reliability of the chip.

In the field of micro and nanomaterials science, accurate measurement and analysis of surface morphology is crucial for understanding the properties of materials, optimizing manufacturing processes, and developing new materials. 3D tool microscopy, as a high-precision, non-contact measurement device, shows great potential for application in the surface morphology analysis of micro and nanomaterials.

I. High Precision Measurement

3D tool microscopes are capable of capturing extremely minute details on the surface of micro- and nanomaterials through advanced optical systems and high-resolution image sensors. Its measurement accuracy usually reaches the nanometer level, enabling scientists and engineers to accurately obtain three-dimensional topographic data of the material surface, including height, roughness, corrugation and other key parameters.

II. Non-contact Inspection

Compared with traditional contact measurement tools, 3D tool microscope uses non-contact detection to avoid damage to the material surface during the measurement process. This is especially important for micro and nano materials, as their surfaces are often very fragile, and any minor scratches or damage may affect the overall performance of the material.

III. 3D Visualization and Data Analysis

The 3D tool microscope is not only able to provide high-precision measurement data, but also able to display the measurement results in the form of three-dimensional images. This three-dimensional visualization function allows scientists to intuitively observe and analyze the material surface morphology features, such as bumps, depressions, cracks, etc.. At the same time, combined with professional data analysis software, the measurement data can also be further processed and analyzed to extract more useful information.

In the semiconductor manufacturing process, 3D tool microscope can be used to detect tiny defects and contamination particles on the chip surface. By accurately measuring and analyzing its surface topography, problems in the manufacturing process can be detected and corrected in time, improving the quality and reliability of the chip.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION