Comparison of in-line image measurement phases and traditional measurement tools

Through the non-contact, high precision, automation and intelligent characteristics, the online image measuring instrument solves the limitations of traditional tools such as low efficiency, poor adaptability and weak data management, and becomes the core tool for the intelligent upgrading of industrial production.

Non-touch measurement to protect the object to be measured

Traditional measuring tools (e.g. calipers, micrometers) need to touch the object to be measured, which may lead to surface damage or deformation, and are especially unsuitable for fragile materials (e.g. thin plates, soft components). In-line image measuring instruments utilize optical imaging technology to achieve non-contact measurements, avoiding the errors and damage associated with physical contact.

High precision and stability

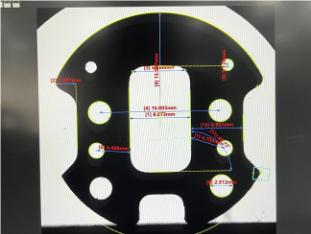

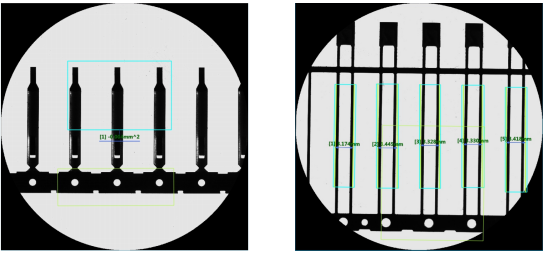

The in-line image measuring instrument utilizes a high-resolution camera and image processing algorithms to achieve micron-level or even higher accuracy (e.g., 0.1μm), far exceeding the millimeter-level accuracy of traditional tools. At the same time, intelligent algorithms can automatically compensate for environmental disturbances (e.g. light, temperature changes) to ensure stable and reliable measurement results.

Efficient automation for increased productivity

Traditional tools rely on manual operation, which is slow and susceptible to human error. In-line image measuring instruments support batch automatic measurement, capturing images quickly and generating results in real time, significantly shortening inspection cycles. For example, millisecond response can be realized in the production line, providing instant feedback on whether the product size is OK/NG.

Real-time monitoring and data traceability

While it is difficult to realize real-time monitoring of the production process with traditional measurements, the online image measuring instrument can be embedded in the production line, collecting data in real time and uploading it to the cloud synchronously, supporting remote viewing and analysis. Historical data can be traced back, facilitating quality tracing and process optimization, and improving production management efficiency.

Intelligent and convenient operation

The interface of the online image measuring instrument is friendly and supports one-button operation and program editing, so it can be operated quickly without the need for professionals. Its AI algorithm can automatically identify features (e.g. edges, contours), reducing manual intervention and operational difficulties.

Wide range of application areas

Applicable to electronics, automotive, aerospace, medical and other industries, especially in the tiny precision parts (such as cell phone camera cover, chip pins) and complex curved surfaces (such as curved metal parts) measurement of significant advantages. Traditional tools are often difficult to meet the needs in these scenarios.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com