Tool microscope definition:

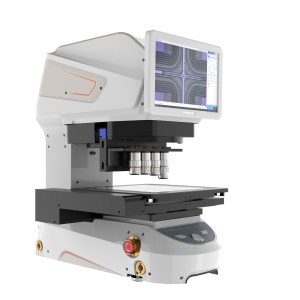

Tool microscope is a high-precision instrument combining optical magnification and precision coordinate measurement functions, belonging to optical metrology equipment. It magnifies the image of the object through the optical system, and utilizes the mechanical or digital display system for non-contact measurement of the geometric size, angle, contour, etc. of the tiny workpieces, which is widely used in the fields of industrial manufacturing, quality inspection and scientific research.

How a tool microscope works:

1、Principles of Optical Imaging:

① Light source and lighting system: illuminates the object to be measured by transmitted light (bottom light source) or reflected light (top light source) to ensure clear contrast.

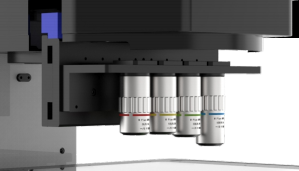

② Objective lens and eyepiece: the objective lens will magnify the object into an image, and the eyepiece will further magnify it for the human eye to observe (total magnification = objective lens magnification × eyepiece magnification, e.g., 10 × objective lens + 10 × eyepiece = 100 times).

③ Dividing plate and ruler: the eyepiece has a built-in dividing plate (a piece of glass with a scale), which is used to assist in positioning or preliminary measurements.

2、Coordinate measuring system:

① Mechanical moving platform: the carrier table can be moved in the X/Y direction by precision screw or guide rail, and the movement is read by rotating dial or digital display device (the accuracy is usually 1-10 microns).

② Angle Measurement: The carrier table or eyepiece can be rotated and combined with an angle scale or digital angle encoder to measure the tilt angle or arc radius of the workpiece.

3、Data processing: Modern tool microscopes are mostly equipped with digitizing systems, which can directly input the measurement data into a computer to generate 2D graphics or export CAD models (for reverse engineering).

Tool Microscope Core Uses

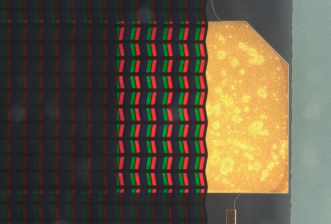

1. Industrial Inspection and Quality Control: Measurement of dimensional tolerances, shape errors (roundness, straightness), etc. of precision parts (e.g., gears, threads, stampings) to ensure compliance with drawing requirements; detection of defects (short-circuits, soldering deficiencies) in electronic components (e.g., PCB solder joints, chip pins).

2. Reverse engineering: Generate digital models by measuring the contours of complex parts point by point for replicating or improving designs.

3. Mold and tool calibration: Measurement of mold cavity depth, hole diameter, tool cutting edge angle and other parameters to assist in machining accuracy control.

4. Scientific research and teaching: material surface microscopic morphology analysis, mechanical structure research, or for teaching demonstration of precision measurement methods.

Tool Microscope Advantage

(1) High precision and non-contact measurement: the resolution can reach micron level (e.g. 1μm), avoiding the damage to fragile workpieces caused by contact measurement.

(2) Multi-functionality: supports multi-parameter measurement of length, angle, contour, coordinates, etc., and is suitable for analyzing complex geometries.

(3) Intuitive and easy to use: Optical magnification of the image directly shows the details, with digital display system to quickly read the data, the threshold of operation is lower than the Coordinate Measuring Machine (CMM).

(4) Strong adaptability: can measure metal, plastic, ceramics and other materials, compatible with transparent/opaque objects (by switching the light source mode).

Through the principle of “optical imaging + coordinate measurement”, tool microscope combines the visualization of microscopic morphology with the quantification of data, becoming an indispensable inspection tool in the field of precision manufacturing. Its core value lies in realizing high-precision and multi-parameter measurement in a non-contact way, which significantly improves the quality control efficiency of industrial production and the accuracy of scientific research and analysis.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com