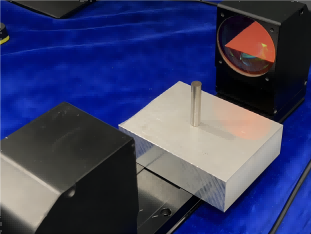

Through the integration of “optical-machine-electrical-soft” technology, the online image measuring instrument solves the problems of low efficiency, poor accuracy and data silo of the traditional screw inspection, which is especially suitable for high-precision manufacturing fields such as automotive, aerospace, 3C electronics, etc., and helps enterprises to realize intelligent and zero-defect production.

Efficient batch inspection for improved production efficiency

1. Fully-automatic scanning: no need for manual item-by-item measurement, continuous batch testing of screws (e.g. hundreds per minute), suitable for assembly line high-speed operation.

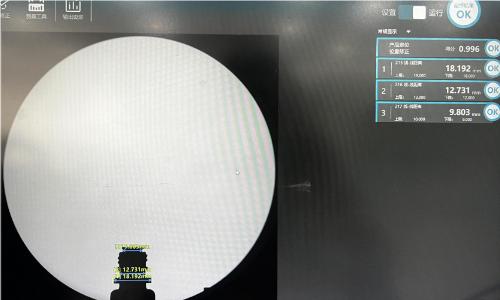

2. Multi-parameter simultaneous measurement: a single scan can obtain all the parameters such as diameter, pitch, tooth angle, head size, etc., which improves the efficiency by more than 80%.

Micron-level high accuracy, eliminating manual errors

1. Optical resolution of 1μm: accurately capture thread details (e.g. ±0.1° tooth angle deviation), far exceeding traditional tools such as calipers and micrometers.

2. AI algorithm calibration: automatically compensates for environmental disturbances (e.g. temperature fluctuations) to ensure stable repeatable measurement accuracy.

Non-contact measurement to protect surface quality

1. Zero-contact anti-wear: Avoid scratches on plating or precision threads caused by traditional contact tools (e.g. thread gauges).

2. No risk of deformation: especially suitable for measuring miniature screws (e.g. below M1) or deformable materials (e.g. aluminum alloy).

Data traceability and standardized management

1. Full-process data recording: automatically generate reports (with images, dimensions, tolerance comparisons) for measurement results, support ISO/GB and other standard formats for export.

2. SPC statistical analysis: real-time monitoring of production fluctuations, quickly locate process problems (e.g., mold wear caused by the deviation of the thread center diameter).

Flexible adaptation to complex scenarios

1. Compatible with multi-size screws: through the software to switch the detection program, no need to change the hardware to measure different sizes (such as M2-M30), head type (hexagonal, countersunk head) of the screws.

2. Suitable for harsh environments: dustproof and anti-vibration design, stable operation in oil and dusty workshop.

Reduced overall costs

1. Labor saving: 1 set of equipment can replace 3-5 quality inspectors, long-term cost reduction of more than 50%.

2. Reduce scrap rate: real-time feedback on production deviation, avoiding batch rework.

Intelligent integration and remote control

1. Seamless docking production line: linkage with PLC and robotic arm, automatic sorting of non-conforming products.

2. Cloud management: support remote monitoring and data sharing, realize multi-plant collaborative quality inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com