In the field of industrial inspection and precision manufacturing, microscope is experiencing the intelligent transformation from “people adapting to equipment” to “equipment serving people”. The essential difference between traditional zoom microscope and electric zoom autofocus microscope essentially reflects the leapfrog evolution of optical instruments from the mechanical era to the digital era.

Focusing Methods: A Revolution in Efficiency

Conventional microscopes rely on the operator to manually rotate the focus wheel, requiring the naked eye to continuously judge image sharpness. This requires a high level of operator experience, especially at high magnification of 500X, where focusing errors may lead to loss of critical details. The motorized AF system, however, analyzes image contrast in real time through the CMOS sensor and completes precise focusing within 0.3 seconds, which is equivalent to digitizing the professional inspector's focusing experience. Measured data shows that it can improve work efficiency by 60% in batch inspection.

Light source systems: dimensional breakthroughs

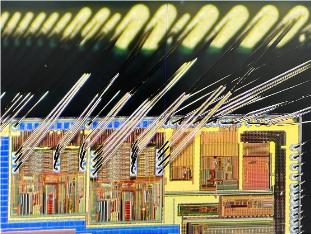

Traditional one-piece light sources are like single-point bulbs, which tend to produce shadow masking when observing complex structures. Quadrant LED light source system can eliminate more than 90% of the observation blind spots by independently controlling the brightness ratio of the four quadrants (maximum brightness difference up to 1:5). This is crucial for PCB board inspection, precision molds and other samples with three-dimensional structure, equivalent to the microscope equipped with a “ring shadowless lamp”.

Optical performance: a jump in resolution

Ordinary zoom lenses often show chromatic aberration phenomenon above 100X, while POMEAS HD lens adopts double gluing achromatic technology, which still maintains 2μm linewidth resolving capability under 500X magnification. What's more, the optical axis shift during zoom is controlled within ±1μm, which ensures the consistency of observation benchmarks under different magnifications.

Software Enablement: Functional Evolution

While traditional microscopes exist only as “optical magnifiers”, the software system of an intelligent microscope is equivalent to a second optical system. The non-contact measurement function realized by the image algorithm can reach an accuracy of ±0.5%. What's more, it supports customized measurement templates, for example, in electronic component inspection, it can preset the standards of key parameters such as pin spacing, solder joint diameter, etc., and realize automatic compliance judgment.

In production line inspection and other scenarios that require repetitive operations, intelligent microscopes have shown irreplaceable advantages. In the actual factory inspection, the motorized zoom auto focus microscope is more suitable both in terms of working efficiency and operational use.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com