The importance of flange centricity measurement

Flange concentricity is a key parameter in flange manufacturing and installation, which directly affects the sealing of pipeline connection, structural stability and equipment safety. Excessive deviation of centricity may lead to uneven stress on the flange surface, sealing failure (e.g. leakage of chemical medium) or stress concentration in mechanical parts (e.g. breakage of ship pipelines). Especially in high-pressure, high-temperature or corrosive environments, accurate roundness control is the basis for system reliability.

Flange circularity (roundness) is an assessment of how close the flange cross-section is to the theoretical circle, i.e. how much the actual contour of the flange bore deviates from the ideal circle. Its measured value directly reflects flange machining accuracy and is a key parameter in ensuring the sealing and stability of equipment connections.

Industry pain points

Traditional methods are difficult to meet the triple demands of modern industry for high accuracy, high efficiency and high reliability, especially in large flanges or complex working conditions, where measurement errors may lead to serious safety hazards.

Solution

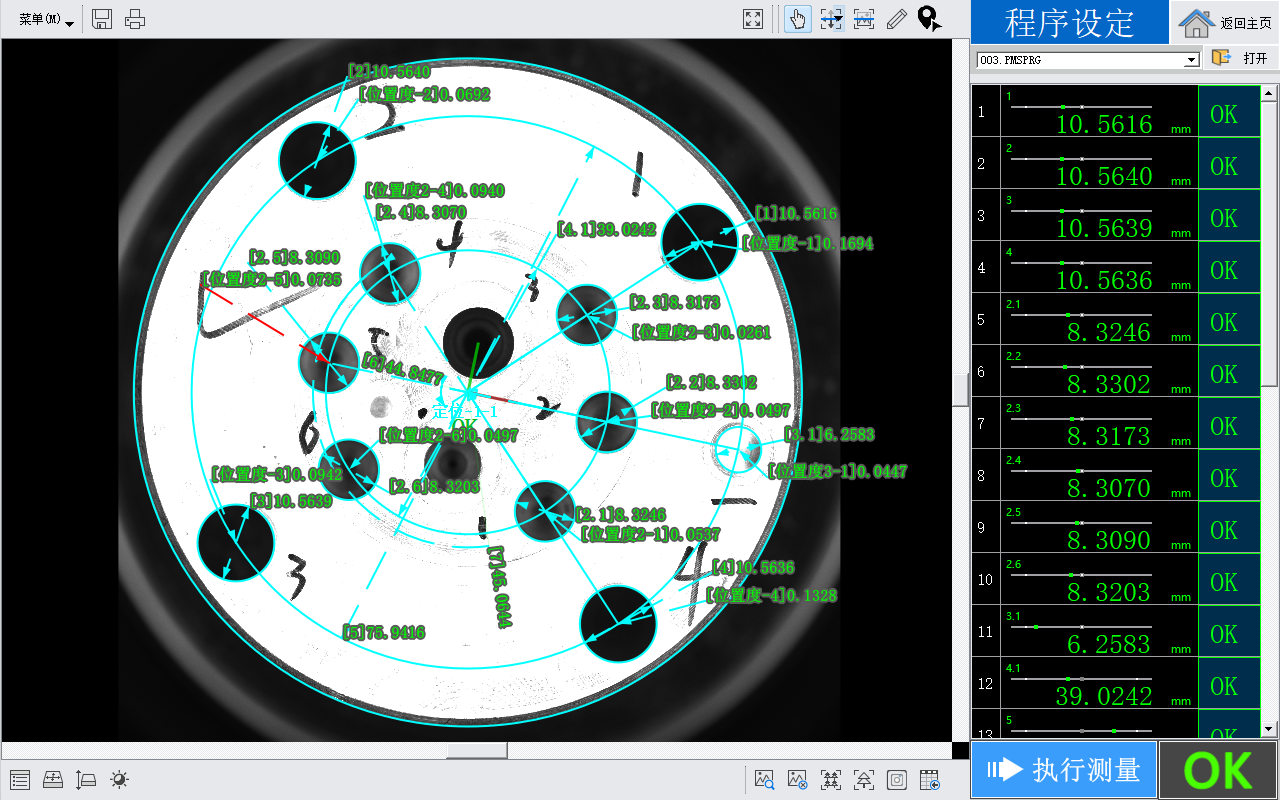

Flash measuring instrument can be fully automatic recognition of the measurement with just one key, which can solve the problems of low precision and poor consistency of traditional manual measurement, fast measurement speed, second results, can complete the measurement of flange roundness with high precision and high efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION