Laser sensor is a new type of measuring instrument, which utilizes laser technology for measurement, and has the advantages of no contact, long distance, fast speed, high accuracy, large range, and strong resistance to optical/electrical interference.

What are the types of laser sensors? Sensors can be categorized according to their mode of operation and measurement range: “point, line and surface”.

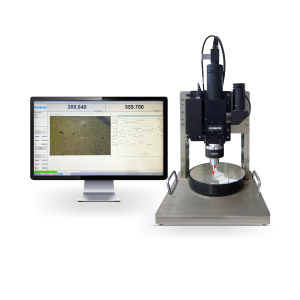

A、Point Laser Sensor

1. Definition: Point laser sensors measure by emitting a focused beam of laser points, with high precision and long-distance measurement capability. Its focused laser beam is suitable for small-area, high-precision inspection scenarios, but the measurement efficiency is relatively low and requires point-by-point scanning.

2. Appliance:

(1) Precision Manufacturing and Processing: Used to measure the size and surface topography of tiny parts, such as semiconductor chip inspection and precision mold measurement.

(2) 3D scanning and reverse engineering: as the basis of point cloud data acquisition, used to reconstruct the object 3D model.

(3) Scientific research and medical treatment: Microscopic measurements in the laboratory, or for precise positioning in medical equipment.

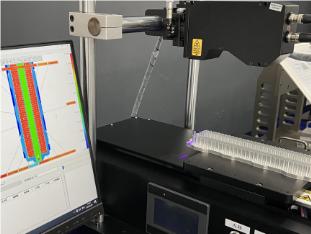

B、Line Laser Sensor

1. Definition:The line laser sensor projects a laser line onto the surface of the object to be measured, and obtains the contour information of the object through the principle of laser triangulation. It has the advantages of non-contact measurement, high accuracy, suitable for complex shapes and irregular objects, can measure multiple dimensions at the same time, high efficiency, etc.; it adopts laser line projection and CCD/CMOS camera reception, and combines with spot processing algorithms to realize sub-millimeter accuracy.

2. Appliance:

(1) Industrial automation: robot vision guidance: assisting robotic arm gripping and assembly; assembly line inspection: real-time measurement of object size and position, such as automotive parts size inspection.

(2) Aerospace: detecting contour defects in aircraft engine blades, fuselage structures.

(3) 3D printing and modeling: scanning the surface of the printing layer to ensure printing accuracy.

(4) Metal Processing: Measure the flatness of metal sheets, weld quality.

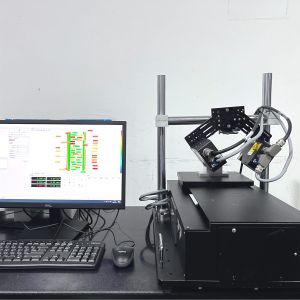

C、Surface Laser Sensor

1. Definition: The surface laser sensor projects a laser surface onto the surface of the object to be measured, realizing large-area measurement. It has the advantages of fast measurement speed, suitable for dynamic scenes or large-area object detection, etc.; the laser surface uniformity control is complicated, and a large amount of data processing is accomplished.

2. Appliance:

(1) Logistics and warehousing: fast scanning of the surface of goods for volume measurement and classification.

(2) Intelligent transportation: monitoring road surface conditions, vehicle contours, for overlimit detection.

(3) Agricultural automation: Measuring pest and disease areas on the surface of crops to assist precise spraying.

(4) Security monitoring: Combine with AI recognition to detect the shape and location of intruding objects.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com