Non-destructive testing is a technology that detects surface defects or surface contour scans and 2D dimensions of an object by physical methods without destroying its structure or affecting its usability. It is widely used in aerospace, automotive manufacturing, electronics, construction and other industrial fields, is to ensure product quality and equipment safety inspection program.

What are the NDT programs?

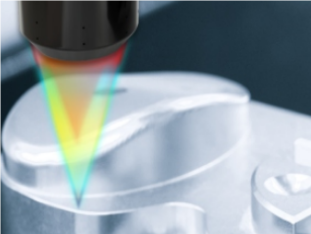

Line Laser Profile Scanner:

1. Working Principle: Project the laser line to the surface of the object through the line laser light source, use the high-speed industrial camera to capture the position of the reflected light, combined with the principle of triangulation to calculate the object's three-dimensional contour coordinates; capture hundreds of thousands of points per second, to generate a high-precision three-dimensional model to support the motion control to achieve continuous contour scanning.

2. Application Scenario: Widely used in the fields of railroad, medical treatment, cultural relics restoration and topographic mapping.

Flash Meter:

1. Working Principle: Adopting large field of view, low distortion double telecentric lens imaging, the image of the object is narrowed down and passed to the high-resolution CMOS camera; the background software quickly grabs the contour and compares it to calculate the size through sub-pixel edge extraction and preset programming commands.

2. Application Scenario: Suitable for large-scale, automated quality inspection, such as precision hardware, 3C electronic parts and so on.

Visual Image Measurement Program:

1. Working principle: use zoom lens to zoom in 2D image synchronously, generate 3D point cloud through image alignment and 3D reconstruction algorithm; combine with structured light/motion control to realize complex surface scanning.

2. Application Scenario: Inspection of three-dimensional spatial points, dimensions or contours of large workpieces.

Point Spectral Measurement Program:

1. Working principle: using spectral sensors to emit a specific wavelength of light, by detecting the spectral characteristics of the object reflected or absorbed, to analyze the surface material, thickness or composition.

2. Application Scenario: Wafer, cell phone screen and other transparent material thickness measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION