In the production and quality control of metal probes, accurate observation of microscopic features such as defects, scratches, losses, etc. on the surface of the probes is a critical part of ensuring product quality. The motorized zoom autofocus microscope has become an indispensable inspection tool in this field due to its excellent performance and convenient operation.

As an important part of precision instruments, the surface quality of metal probes is directly related to the performance and reliability of products. In the production process, the probe needs to be observed in all aspects, including but not limited to the following aspects:

1. Defect detection: internal or surface defects such as bubbles, inclusions, cracks, etc., which may affect the mechanical and electrical properties of the probes.

2. Scratches and abrasion: during processing, transportation or use, the surface of the probe may be scratched or abraded, affecting its accuracy and life.

3. Dimensional and form accuracy: the dimensional and form accuracy of the probes is critical to their effectiveness in assembly and use in the instrument.

However, microscopic observation of metal probes faces many difficulties:

- Observation object is small: the microscopic features such as flaws and scratches on the probe are small in size and require a high magnification microscope for clear observation.

- Complex observation surface: the surface of the probe may have complex shape and texture, which increases the difficulty of observation.

- High observation environment: in order to obtain clear images, a stable observation environment and suitable light source conditions are required.

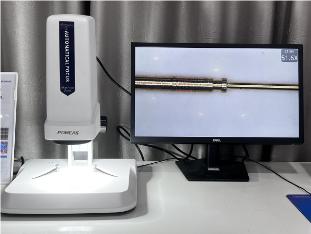

With its unique design and functions, the motorized zoom autofocus microscope effectively solves the difficulties in the observation of metal probes and provides powerful support for production quality control.

1. Motorized zoom and autofocus: Allow users to easily switch between different magnifications according to their needs, from observing the overall shape of the probe at low magnification to analyzing microscopic features such as imperfections, scratches, and losses on the surface of the probe in detail at high magnification; and through the built-in motorized zoom lens, samples instantly show a clear imaging effect, which greatly improves the accuracy and efficiency of the observation.

2. Simple Measurement Function: The microscope comes with a simple measurement function, which can easily measure the product dimensions of the metal probe, such as length, diameter and other key dimensions, to ensure that the product meets the design requirements; the measurement results can be displayed on the microscope's display in real time, which is convenient for the user to record and analyze, and provide data support for quality control.

3. Flexible dimming system: Adjust the brightness and angle of the light source according to the different observation environments to ensure that the observation area has sufficient and uniform light; this function is particularly important when observing metal probes, because the surface of the probe imperfections, scratches and other microscopic features often need to be clearly presented in a specific light conditions.

Motorized zoom autofocus microscopes can be applied in several stages of the inspection process in the production of metal probes:

- Raw material inspection: observe the microstructure and impurities of raw materials through microscope to ensure the quality of raw materials meets the production requirements.

- Process monitoring: during the processing of the probe, observe the flatness, roughness and scratches of the processed surface through the microscope, and adjust the processing parameters in time to avoid the production of defective products.

- Finished product inspection: in the finished product inspection stage of the probe, the dimensional accuracy, surface quality and functional performance of the probe are observed through the microscope to ensure that the quality of the finished product meets the design requirements. At the same time, the microscope's simple measurement function is utilized to measure and record the key dimensions of the probes.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com