Gear Inspection Difficulties:

1. High precision requirements: gear tooth pitch deviation is usually required to be at the micron level (error ≤ 10μm), which puts forward extremely high requirements on the precision and stability of the measuring equipment.

2. Difficulty in the selection of measurement reference: the measurement reference of gears is usually the design reference (e.g. indexing circle, toothed circle), but in the actual measurement, the selection and positioning of the reference may be affected by the gear mounting error, fixture accuracy and other factors.

3. Measurement of complex tooth shapes: Helical gears, bevel gears, worm gears and other complex tooth shapes need to take into account the helix angle, pressure angle and other parameters, which increases the difficulty of measurement.

4. Measurement of large-size gears: large gears are large in size and heavy in weight, which are difficult to be installed and measured on conventional measuring equipment, and need to be measured on-machine or large-scale specialized equipment.

Gear Inspection Equipment:

1. Coordinate Measuring Machine (CMM): suitable for the measurement of geometric parameters of complex gears, but need to be equipped with special probes and software.

2. Universal Tool Microscope (UTM): suitable for tooth pitch and tooth shape measurement of small and medium modulus gears, but less efficient.

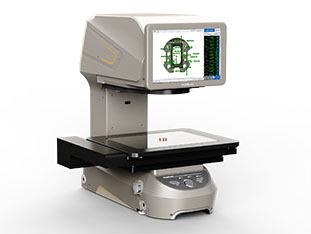

3. Image Dimension Measuring Instrument (Flash Measuring Instrument): Quickly measure product dimensions and product contour scanning with just one click.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION