Beginner's Guide | Online Image Measuring Instrument Application Scenarios

Under the rapid development of the industrial field, the online image measuring instrument HM series is reshaping the quality inspection system of the modern manufacturing industry by virtue of its non-contact, high-precision and intelligent technology advantages. This device, which integrates optical imaging and automation control, is especially suitable for responding to precision measurement needs in complex industrial scenarios.

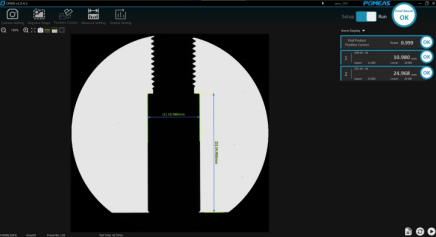

Geometric Inspection of Precision Parts

In the field of metal processing and machinery manufacturing, it can measure all kinds of parts with a diameter of 0.01-120mm in real time. Through multi-angle imaging technology, it can accurately capture parameters such as outer diameter, height, concentricity, etc. The measurement accuracy of complex contours such as threaded teeth, gear involute, etc. can be up to ±0.0001mm. it is especially suitable for detecting key parts such as engine cylinder block and hydraulic spool, etc., and effectively solves the problems of low measurement efficiency and contact wear of traditional calipers.

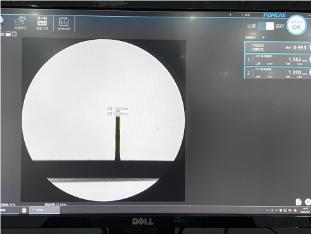

Stability monitoring of dynamic production lines

For automated production lines with conveyor speeds up to 2m/s, the device is equipped with a high-speed CMOS sensor (up to 5,000 frames per second) that freezes the motion trajectory and, combined with adaptive filtering algorithms, maintains measurement stability within a ±15° swing of the part.

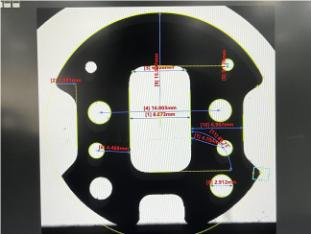

Measurement of defects in electronic components

A contour is extracted from the edge of the workpiece and parts that differ significantly from this contour line are identified as burrs, defects or foreign objects. The online image measuring instrument is used to measure the distance from the extracted contour to the front of the foreign object. It supports not only straight line or circle detection, but also detection of complex shaped contours consisting of free curves such as wavy surfaces.

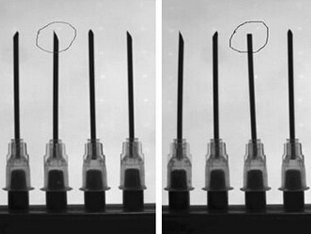

Medical Device Compliance Verification

It can measure the length and diameter of syringe tips and high-precision dimensions of medical surgical tools in a sterile testing environment.

Packaging integrity testing of pharmaceuticals and vials

On a high-speed blister packaging line (300 plates/minute), the number of pills is detected and the size is measured. By establishing a database of drug appearance characteristics, it can automatically identify abnormalities such as mixed batches and mixed specifications; and measurement of the appearance size of pill bottles, and thread measurement of bottle caps.

3D Dimensional Reconstruction of Shaped Parts

For workpieces such as turbine blades, telecentric optical system projection scanning technology is used to obtain appearance profile data in a single measurement, and full-size comparisons can be completed within 5 minutes.

Online image measuring instruments are evolving from single size inspection to intelligent quality management system. Its application boundary has been extended to new energy battery pole piece inspection, semiconductor wafer measurement and other cutting-edge fields, becoming an indispensable quality guardian in the era of intelligent manufacturing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com