In the field of precision inspection and automated measurement, laser autofocus microscope system is widely used in material analysis, industrial quality inspection and scientific research scenarios due to its high accuracy, high efficiency and non-contact measurement advantages.

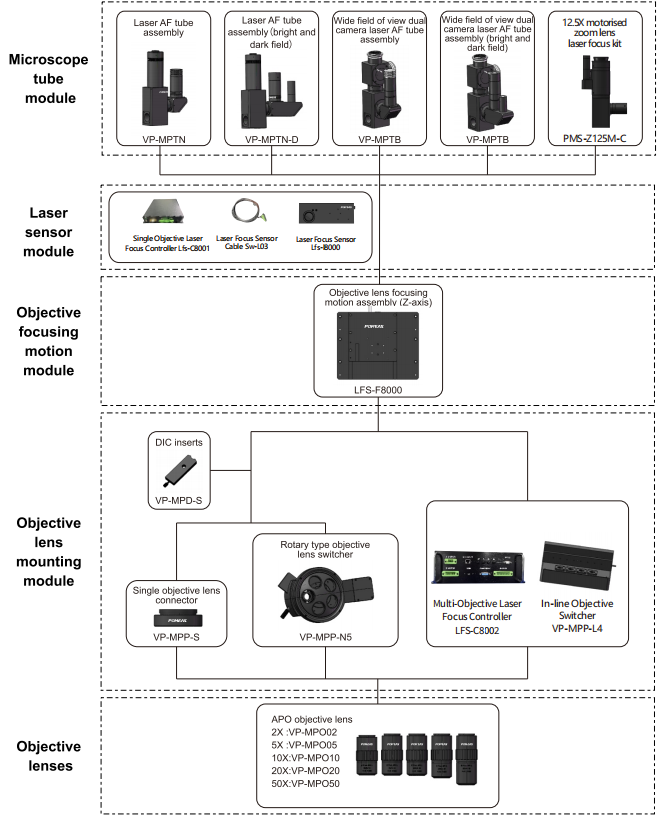

A、System Architecture and Core Modules

The laser autofocus microscope consists of five modules that work together to achieve stable, accurate and automated measurements:

1. microscope tube module: optical imaging core, determining the imaging quality and detection range;

2. laser sensor module: realizes auto-focus and distance sensing;

3. objective lens focusing motion module: drive the objective lens to complete precise focusing;

4. objective lens mounting module: to ensure the stability of the objective lens switching and fixation;

5. objective lens: directly determine the magnification and resolution.

B、Module Selection

1. Microscope tube module

(1) Bright-field and dark-field mirror tube: compatible with bright-field and dark-field illumination, suitable for surface topography analysis (e.g. scratches, particles) and transparent material inspection;

(2) Dual camera tube: integrated dual-channel imaging, supporting multi-dimensional data acquisition under the same field of view (e.g. morphology + spectral analysis);

(3) Zoom tube: continuous zoom design (e.g. 0.7X-4.5X), covering a wide range of inspection needs, reducing the tedious operation of frequent replacement of objective lenses.

2. Laser sensor and objective lens motion module: self-developed technology to ensure accuracy

(1) Laser sensor module: POMEAS self-developed LFS series laser controller, integrating high-precision laser transmitter and receiver units, supporting dynamic focus compensation, and adapting to the stable measurement of metal, ceramics, mirrors and other highly reflective materials;

(2) Objective lens focusing module: also based on LFS series technology, it realizes nano-scale focusing precision through closed-loop control, and is compatible with auto-focusing on deep holes, slanted surfaces, curved surfaces, and other complex shapes.

3. Objective lens mounting module: flexible switching and stability

(1) Single-head connector: lightweight design for single objective lens fixation scenarios;

(2) Inline switcher: supports multiple objective lenses arranged in a straight line, quickly switching between different magnifications;

(3) Carousel switcher: high-density integrated design, can carry up to 6-8 objectives, suitable for multi-task parallel detection.

4. Objective lens selection: covering full magnification requirements

(1) Low magnification (2X-10X): large field of view scanning, suitable for the overall shape of the workpiece inspection;

(2) Medium magnification (20X-50X): balanced resolution and depth of field, suitable for regular size measurement;

(3) High magnification (60X-100X): microstructure analysis, such as semiconductor chips, metal grain detection. Objective lens selection: covering the full magnification requirements

C、System Technical Advantages

1. material compatibility: stable measurement of metal, ceramic, mirror, glass and other highly reflective or low contrast materials;

2. topographic adaptability: accurately capture complex features such as deep holes, beveled surfaces, curved surfaces, etc., and support the measurement of height, segment difference, thickness, flatness, contour and other parameters;

3. lightweight structure: modular design reduces system weight, easy to integrate into automated production lines or handheld devices;

4. industry adaptability: has been verified in 3C electronics, semiconductor, automotive manufacturing, biomedical and other fields, to meet the needs of multi-scenario automated measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com