Golden Rule of Selection:

(1) precision measurement: prioritize low distortion lens + small pixel CMOS combination

(2) high-speed detection: choose the global shutter + CameraLink interface program

(3) low-light environment: large pixel CCD with optical gain technology

(4) cost-sensitive: USB3.0 interface 1/1.8" CMOS cameras

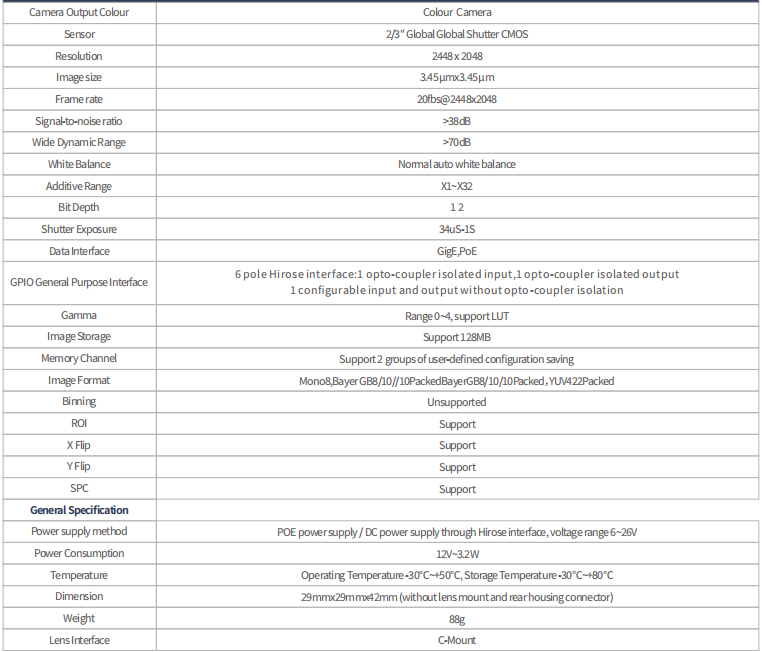

POMEAS industrial camera PMS-CCN-050E15CSC example:

Pixels vs. Resolution:

The total number of pixels = horizontal pixels x vertical pixels, which directly affects image clarity. When inspecting electronic components with 0.1mm accuracy, a 2 megapixel camera with appropriate optics can meet the demand, while micron-level defect detection requires 12 megapixels or more. Note: Higher pixels will reduce the frame rate, so you need to balance speed and accuracy.

Sensor Type:

CCD excels in low-light environment detection by virtue of its high dynamic range and low noise characteristics; CMOS is more suitable for high-speed assembly line detection by virtue of its low power consumption and high frame rate advantages. The emerging BSI-CMOS technology is breaking through the traditional performance boundaries.

Image Size:

Individual photoreceptor size (commonly 2.4-10μm) determines light capture capability. Large pixels (e.g. 5.86μm) provide better noise control at low light levels, but at the expense of spatial resolution. Smaller pixel (3.45μm or less) models are recommended for precision measurements.

Size of Target Surface:

Sensor diagonal size (1/3“-1.1”) needs to be matched to the lens target plane. Large target plane cameras (2/3“ and larger) with telecentric lenses allow for a larger field of view, while small 1/2” target planes are better suited for compact equipment integration.

Frame Rate Performance:

Ranging from 30fps to 3000fps, chip package inspection typically requires ≥100fps, while high-speed motion analysis (e.g. ballistic tracking) requires a high-speed camera with 1,000 fps. Note that the actual frame rate is governed by a combination of exposure time and transmission interface (GigE/CameraLink).

Gain Adjustment:

Digital gain (0-24dB) improves image brightness but amplifies noise. It is recommended to prioritize the improvement of image quality by extending the exposure time or increasing the intensity of the light source, and the gain can be controlled to 6dB or less in dynamic detection scenes.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION