In the world of precision manufacturing, a single defect in a nut can cause an entire machine to fail. When you are faced with hundreds of nuts flowing at high speed every minute, how can you ensure that each internal thread is perfect and that there are no cracks, burrs or other hidden defects on the inner wall? Traditional manual sampling is like “finding a needle in a haystack”, while the full inspection faces the double challenge of efficiency and cost. Now, let's focus on the industrial vision inspection “eyes of fire” - FA lens, see how it cracks the nut quality inspection problems.

As a core component of industrial vision inspection systems, FA lenses play a key role in the detection of defects in the appearance of nuts. Its technical advantages are reflected in three major dimensions:

1. Microcosmic Insight

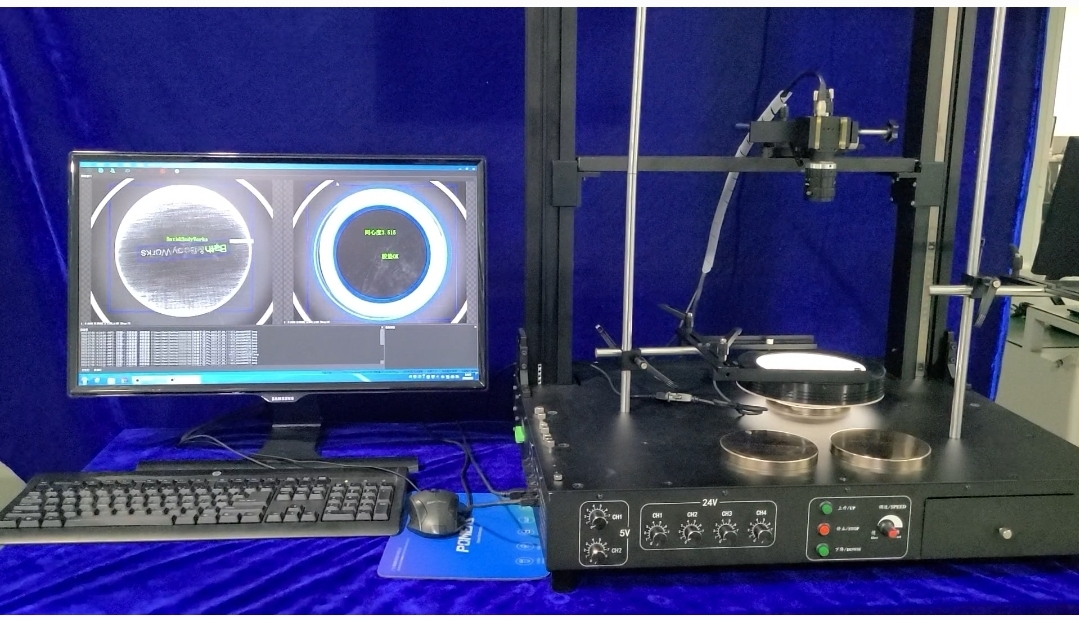

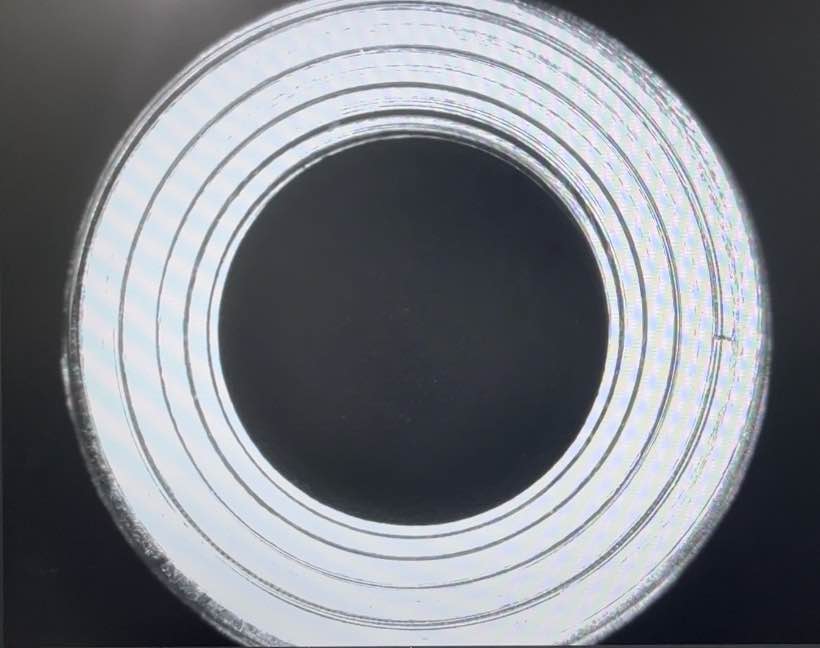

(nut inspection chart)

Paired with a high-definition industrial camera, the FA lens achieves micron-level imaging accuracy. In the nut inner wall inspection scenario, the combination of a coaxial falling light source and low-angle ring light can clearly present the tiny cracks at the bottom of the threaded groove.

2. Expert in Space Structure Analysis

For the visual blind spot of the hexagonal structure of the nut, the FA lens adopts telecentric optical design to effectively eliminate perspective distortion. When inspecting M8 nuts, the system can acquire complete images of the top end face, internal threads and hexagonal sides simultaneously at a working distance of 150mm.

3. Efficiency and Cost Balancer

Compared with the traditional microscopic inspection solution, FA lens solution realizes the inspection beat to be increased to 0.3 seconds/piece, and the overall equipment efficiency (OEE) is increased by 40%. In the field of metal processing: in the aviation connector inspection, FA lens can identify the plating scratches of 0.005mm; in the semiconductor packaging, to realize the chip pin coplanarity ± 2μm precision detection.

From the microscopic world of the inside of a nut to the nano world of a chip pin, FA lenses are reshaping the quality inspection paradigm as the “eyes of industry”. Is your industry facing similar precision inspection challenges? Please share your inspection challenges and let's explore the infinite possibilities of optical technology together!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION