How Online Real-Time Measurement Systems Tighten Production Tolerances

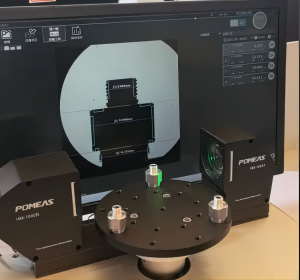

In the field of precision manufacturing, production tolerance directly determines product yield and market competitiveness. Traditional offline inspection methods have a lag time, which makes it difficult to cope with the demands of modern production lines with high tempo and high precision. Telecentric Measurement System HM series provides a revolutionary solution for tolerance control through real-time monitoring and intelligent feedback, becoming the “quality gatekeeper” in the era of intelligent manufacturing.

1. Millisecond Response to Eliminate Bulk Defects

Equipped with high-speed CMOS sensors and sub-pixel algorithms, the HM series can synchronize dimensional measurement and form and position tolerance analysis during the production process, with an inspection speed of up to 2000 times per second. For example, in the production of 3C electronic components, the system can capture tiny deviations of 0.001mm in real time, triggering the equipment to adjust before the first defective product is produced, avoiding the scrapping of the whole batch.

2. Multi-dimensional Data Closure, Accurate Traceability

While traditional testing only provides results, the HM series generates visual trend graphs by integrating the SPC statistical process control module, which correlates and analyzes tolerance fluctuation data with process parameters (e.g., temperature, pressure, speed).

3. Intelligent Compatibility, Empowering Production Line Upgrade

HM series supports IO-Link, Profinet and other industrial protocols, which can be seamlessly connected to robotic arms, AGVs and other equipment to build adaptive production lines.

4. Large Field of View Inspection to Reduce Costs and Increase Efficiency

Single imaging φ40mm~φ120mm area, suitable for full inspection of precision hardware.

In a world where tolerances are measured in microns, the HM series transforms inspection from “after-the-fact remediation” to “real-time control”, helping companies realize zero-defect production. Choosing an online real-time measurement system means choosing to let quality control run before defects occur.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION