The automobile manufacturing industry has very stringent requirements on the dimensional accuracy of components, as even the slightest deviation can affect the overall performance and safety of the automobile. POMEAS IMAGE 3 series of image dimension measuring instruments are the key to ensure the dimensional inspection of automotive parts with their outstanding performance.

I. Accurate measurement, strict quality control

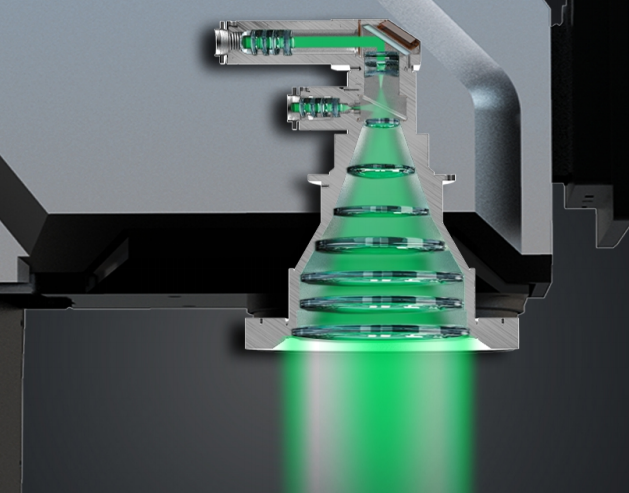

POMEAS IMAGE 3 series adopts high-resolution dual telecentric lenses with advanced image processing algorithms to realize micron-level precision measurement of automotive component dimensions. Taking automobile axle forks as an example, as an important part of the automobile transmission system, the dimensional accuracy of the axle forks is directly related to the stability of the power transmission of the automobile. POMEAS IMAGE 3 series can accurately measure the dimensions of each part of the axle fork to ensure that it meets the strict production standards and guarantees the high quality of automobile manufacturing.

When measuring automotive brake pads, this measuring instrument can accurately detect the dimensions of brake pads such as length, width, distance, R angle, hole depth, thickness, etc., and determine whether they meet the assembly requirements. After assembling the high-precision spectral confocal sensor, it can complete the inspection of brake pads' 2D, thickness, height, segment difference and other dimensions in one time, which can provide a strong guarantee for the safety of automobile braking system.

II. Efficient testing to speed up the production process

The mass production of automotive parts requires efficient inspection equipment. The POMEAS IMAGE 3 series is equipped with the “one-touch flash measurement” function, which is an easy-to-understand operation interface. Simply place the automotive part on the carrier table and start the measurement with one button, no complicated operation steps are required, which greatly improves the inspection efficiency.

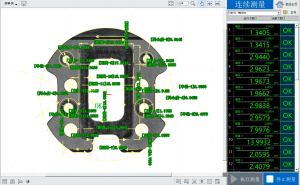

Its large field of view overall imaging function, can be a one-time shot of the full size of the auto parts, without the need to move the lens several times. Take metal flange detection as an example, the measuring instrument can quickly complete the measurement of the flange size, saving a lot of testing time, effectively shortening the automotive production cycle, to meet the needs of the automotive manufacturing industry of large-scale, high-efficiency production.

III. Intelligent functions to enhance detection reliability

The auto-focus function of the measuring instrument can automatically adjust the focal length of the lens to ensure the clarity of the captured image and improve the accuracy of measurement. When detecting the tiny features of automotive parts, the auto-localization function can automatically identify them to ensure the clarity of the image and the accuracy of the measurement. Equipped with POMEAS self-developed spectral lens, it can accomplish 2D and 3D dimension measurement to meet the diversified measurement needs of different auto parts.

After entering the tolerance requirements, the measuring instrument can automatically determine whether the product size is qualified or not, the data is clear and intuitive, and can be saved in various formats for easy checking and tracing at any time, which greatly enhances the reliability and convenience of automotive parts inspection.

The POMEAS IMAGE 3 series of image dimensioning instruments provide a solid guarantee for the quality and efficiency of the automotive manufacturing industry with accurate measurements, efficient inspection processes and intelligent functions in automotive component dimensional inspection, driving the automotive industry forward.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com