In the wave of industrial automation and intelligent manufacturing, industrial camera performance and selection is directly related to the efficiency of the production line and product quality, in the face of a wide range of industrial camera products on the market, how to scientifically and reasonably select the type of the problem faced by many enterprises.

I. Demand Analysis: Clear Selection Goals

Before selecting the model, clarify the application scenarios and needs. Different industrial scenarios have different requirements for industrial cameras, such as: in high-speed production lines, high frame rate industrial cameras are needed to capture fast-moving objects; in precision inspection, high-resolution industrial cameras are needed to capture subtle defects.

II. Analysis of Key Performance Parameters

1. resolution: the resolution determines the image details that can be captured by the industrial camera. Generally speaking, the higher the resolution, the clearer the image, but it will also increase the complexity of data processing. Therefore, you need to choose the right resolution according to the actual needs.

2. sensor type: industrial camera sensor types are mainly CMOS and CCD, CMOS sensors have low power consumption, high integration and other advantages, suitable for most industrial scenes; while the CCD sensor has a higher sensitivity and lower noise, suitable for the image quality of the scene requires a very high level.

3. frame rate: the frame rate indicates the number of images an industrial camera can capture per second. In high-speed production lines, you need to choose a high frame rate industrial camera to ensure that there is no missed inspection.

4. interface and transmission speed: the type of interface (such as GigE, USB3.0, Camera Link, etc.) and transmission speed of the industrial camera directly affect the efficiency of image data transmission. It is necessary to choose the appropriate interface and transmission speed according to the actual needs.

5. environmental adaptability: industrial cameras need to be able to work stably in harsh industrial environments. Therefore, it is necessary to consider the camera's protection level, operating temperature range, vibration resistance and other environmental adaptability indicators.

III. Selection Process and Steps

1. market research: to understand the market mainstream industrial camera brands, models and their performance parameters.

2. preliminary screening: according to the results of the demand analysis, the preliminary screening of industrial camera models to meet the requirements. 3. performance comparison: the preliminary screening of industrial camera performance comparison, including resolution, frame rate, interface and transmission speed, environmental adaptation.

3. performance comparison: the initial screening of the industrial camera performance comparison, including resolution, frame rate, interface and transmission speed, environmental adaptability and other indicators.

4. cost-benefit analysis: comprehensive consideration of industrial camera performance, price, maintenance costs and other factors, cost-benefit analysis.

5. sample testing: select several high-performance industrial cameras for sample testing to verify their performance in practical applications.

Selection of industrial cameras is a complex and detailed process, which requires comprehensive consideration of application scenarios, requirements, performance parameters, cost-effectiveness and other aspects. Through scientific and reasonable selection, it can ensure the stable operation of industrial cameras in the production line and improve production efficiency and product quality.

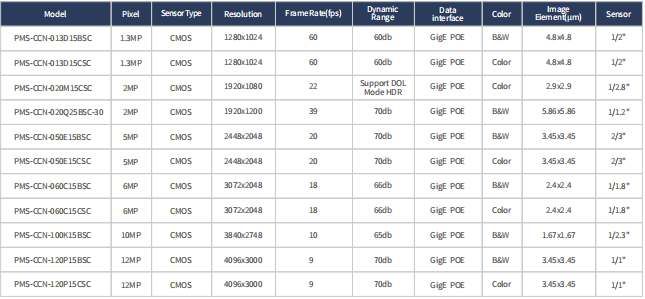

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com