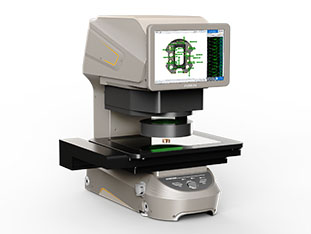

High Precision Precision Measuring Equipment - Image Measuring Instrument

In manufacturing, product quality and dimensional accuracy are closely linked. With its leading technology and excellent performance, POMEAS IMAGE 3 has become a trusted partner for many precision manufacturing companies, injecting a strong impetus for product quality control and productivity improvement.

Advanced technology for ultimate measurement accuracy

POMEAS IMAGE 3 series are equipped with self-developed dual-magnification double-side telecentric optical lenses with high telecentricity, effectively avoiding measurement errors due to object distance variations, which can accurately capture the contours of tiny and complex parts commonly found in precision manufacturing, such as micro gears, precision mold inserts, etc., and achieve micrometer-level precision measurements. The lens provides 0.16X large field of view and 0.7X high-precision two magnification options, the large field of view can quickly scan a large area of parts, grasp the overall dimensional profile; high-precision magnification for the key parts, such as gear tooth shape, mold fine texture, in-depth analysis, not to let go of any dimensional flaws.

The i-Vision AI vision technology equipped in the measuring instrument is a highlight. By integrating CNN neural network and MV machine vision, it can automatically adjust the intensity and color of the dual eight-segment ring light according to the material and surface state of the measured object through the AutoLight function, providing a clear image base for accurate measurement. The AutoFocus function responds quickly and instantly to changes in part thickness, ensuring that the image is always clear and sharp, and the measurement data is accurate and reliable.

Efficient inspection process for mass production

The precision manufacturing industry is characterized by large-scale production, which requires a high level of inspection efficiency. The POMEAS IMAGE 3 series' “One Touch Measurement” function greatly simplifies the operation process. The operator only needs to place the part on the carrier table and press the measurement button, the measuring instrument will start the all-round inspection immediately, and can complete the measurement of up to 50 dimensions in 1 second, and even handle the inspection of 300 parts and 100 targets at the same time, accurately identifying and analyzing all the measured parts from the overall image, without the need for manual positioning and operation, which saves a lot of time and cost.

The measuring instrument has a large field of view measuring range of 300mm×200mm, which can complete the overall imaging of multiple parts or large parts at one time and measure multiple dimensions at the same time. For mass production scenarios, it automatically identifies clusters of parts' feature points through intelligent clustering algorithms, optimizes measurement routes with dynamic path planning, and reduces the waste of measurement time; the parallel processing architecture supports simultaneous data analysis at multiple workstations, which further improves the inspection efficiency. Taking the mass production of cell phone parts as an example, using POMEAS IMAGE 3 series measuring instruments, multiple cell phone housings and internal structural parts can be placed in the measuring area at the same time, and all dimensional inspections can be completed quickly, which improves the efficiency by several times compared with the traditional measurement methods, and ensures the efficient operation of mass production.

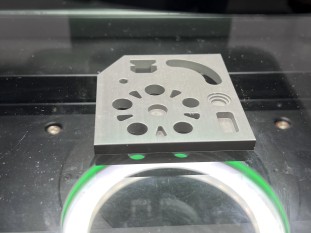

Case Study: Precision Mold Dimensional Inspection

In the past in the mold size inspection link, the use of traditional measuring equipment, complex operation, low efficiency, and for the mold complex curved surfaces, shaped holes and other parts of the measurement accuracy is difficult to ensure, resulting in a high rate of mold scrap, a serious impact on the economic benefits of enterprises.

The dual telecentric lenses of the POMEAS IMAGE 3 series clearly capture the complex contours of the mold, and advanced algorithms automatically identify and calculate key dimensional parameters such as surface curvature, aperture diameter, and slot depth. During the measurement process, all dimensions can be inspected with a single click, without the need for cumbersome clamping. Measurement data is displayed and stored in real time, and compared with the preset tolerance, it automatically determines whether the mold is qualified or not.

POMEAS IMAGE 3 series of dimensional measuring instruments, with its advanced technology and efficient inspection process, occupies a key position in dimensional inspection in the precision manufacturing field, helping enterprises to improve the quality of their products and enhance their competitiveness in the market, and becoming an important force for the development of the precision manufacturing industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com