Limitations of conventional gear measurement techniques

Traditional gear inspection mainly relies on two-dimensional image measuring instruments, micrometers and other contact measurement tools. Although the image measuring instrument can realize non-contact detection, but limited by the two-dimensional imaging principle, the helix angle of the gear, tooth deviation and other three-dimensional parameters of the measurement of the blind spot. Micrometer measurement requires point-by-point contact measurement, single-parameter measurement takes as long as 20-30 minutes, and requires high operator skills.

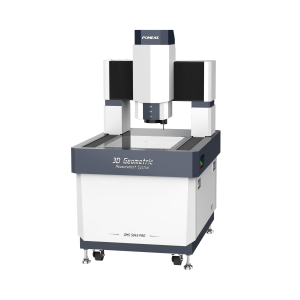

POMEAS Multi-Sensor Measurement System redefines the industrial inspection standard with a revolutionary technology architecture in the era of “micron-level” precision manufacturing. The system deeply integrates the intelligent sensing capability of machine vision and the millimeter-level spatial resolution of 3D laser scanning to build a holographic inspection matrix covering “macro-appearance and micro-features”.

Relying on the self-developed heterogeneous sensor fusion algorithm, the system can synchronously capture 12 core parameters such as gear tooth profile, helix angle, tooth pitch deviation, etc., and complete the closed-loop inspection of full-size gears with modulus spanning 0.5-20mm in 180 seconds, with the measurement repeatability breaking through to ±1.5μm, which is an increase of 400% in the efficiency of the traditional inspection program and a jump of three orders of magnitude in the accuracy.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION