What are the benefits of dual telecentric lenses in a measurement program?

In fields such as industrial inspection and quality control, measurement accuracy often determines product yield. Have you ever wondered how a flash tester or vision inspection device can capture micron-level errors? The answer may be hidden in its “eyes” - double telecentric lens. Today, we will talk about why this lens can become the “golden partner” of high-precision measurement programs.

Double Telecentric Lens Features

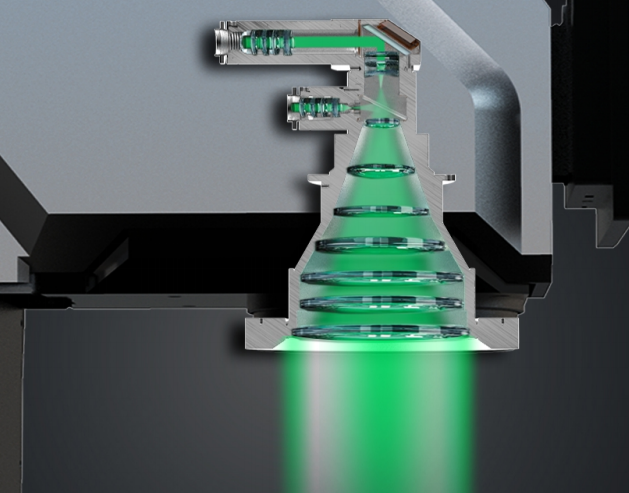

Compared with traditional lenses, the double telecentric lens realizes two major breakthroughs through its unique optical path design:

First, the object is telecentric, to ensure that the measured object is in any position within the depth of field, the size of the image is constant, to avoid the measurement error caused by the displacement of the object;

The second is the image side telecentric, so that the light received by the sensor is always parallel, completely eliminating the uneven brightness of the image caused by changes in the angle of illumination.

Case Studies

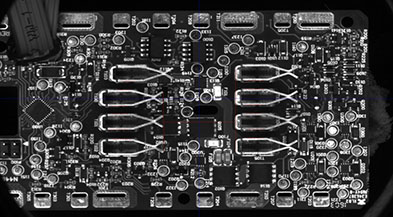

In circuit board defect detection, components are tiny, solder joints are dense, the traditional lens is often due to the lack of depth of field leading to blurring of some areas, or due to the angle of view deviation triggered by the size of the misjudgment. The double telecentric lens with a large depth of field (up to tens of millimeters) and parallel light path characteristics, can clearly capture the details of the entire board at once.

Example: When detecting chip pins with a pitch of 0.5mm, the measurement repeatability accuracy can be improved to within ±1μm, reducing the misjudgment rate by 80%. What's more, even if there is a slight warpage of the circuit board, the dual telecentric lenses can ensure the consistency of the measurement results through constant magnification, which is called a “deformation correction magic weapon”.

The Flash Meter's “Best Partner”: Efficiency and Accuracy At The Same Time

In the flash meter, the role of the double telecentric lens is more prominent. Traditional measurements need to focus several times, sub-area shooting, while the double telecentric lens with a high-resolution camera, can achieve “panoramic depth + full field of view” synchronized imaging, measurement speed increased by 3-5 times.

Cell phone frame detection, for example, the traditional program takes 20 seconds to complete the flatness, hole position and more than 10 tests, equipped with a double telecentric lens flash detector only takes 3 seconds, and the data is directly connected to the production system, the real realization of the “detection - feedback - adjustment” closed loop.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com