The compact Telecentric Measurement System HM series is designed for modern automated production lines and is intended to provide an efficient and accurate solution for real-time in-line dimensional inspection.

Core Strengths :

1. Seamless Integration: The design of the device takes into account the compatibility of the production line, and supports seamless connection with all kinds of automated production lines (such as robotic arms and conveyor systems), realizing the automation of the measurement process.

2. Compact size: compact body, the overall size of the smallest only 370mm, the largest not more than 820mm, can be flexibly deployed in the production line space constraints, easy to realize real-time measurement next to the workstation or line edge.

3. Excellent accuracy: Provides 1μm to 2.5μm high-precision measurement capability to meet the needs of industrial parts inspection with stringent dimensional tolerance requirements.

4. High adaptability: Supporting automatic program switching, it can effectively cope with the continuous online measurement tasks of multi-size and multi-specification products on the assembly line, and improve the flexibility of the production line.

Typical Application Cases :

-

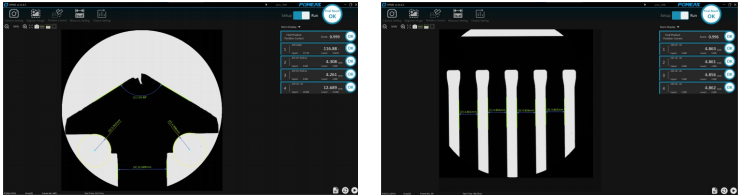

Various types of nuts size and thread inspection

-

Measurement of contours, hole diameters, and spacing of precision metal parts (e.g., bushings, stampings)

-

Critical dimensions (flute length, angle, diameter) and wear detection of tools (e.g. drills, milling cutters, inserts)

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION