In the pursuit of ultimate efficiency and precision in the modern manufacturing industry, flash tester with its revolutionary “flash that is measured” ability, is rapidly replacing the traditional measurement methods, to enhance the efficiency and reliability of quality control of the core equipment. It not only solves the pain point of measurement efficiency, but also raises the measurement accuracy and data management to a new height.

I. What is a Flash Meter?

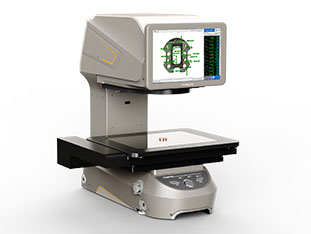

Flash Meter, also known as one-button meter or image measurement system, is a non-contact two-dimensional precision measurement equipment based on high-resolution industrial cameras and precision optical lenses, combined with advanced image processing algorithms. Its biggest attraction is:

-

“Flash” measurement: Say goodbye to the point-to-point cumbersome! Just take a picture (usually less than 1 second), instantly obtain the dimensional information of all the contours of the surface of the workpiece.

-

"One-touch operation: the ultimate in simplicity! Simply place the workpiece and press the button, the system automatically completes the measurement, analysis and judgment, significantly reducing the threshold of operation and human error.

-

"Capture all dimensions: In a single photo, all geometric features such as points, lines, circles, arcs, angles, distances, positional degrees, etc. are at your fingertips, making it dozens or even hundreds of times more efficient than traditional tools!

II. Principle of Operation of the Flash Meter

1. High-precision Imaging Cornerstone: Equipped with a high-resolution CCD/CMOS camera and the key optical component - telecentric lens (eliminates parallax, ensures distortion-free images and accurate magnification), capturing clear details of the workpiece.

2. Intelligent Edge “Eye”: Powerful image processing algorithms automatically and accurately recognize the edge contour of the workpiece and locate every feature point to be measured.

3. Instantaneous geometry calculation: Based on the extracted edge data, the software calculates all preset or automatically recognized dimensional parameters (diameter, length, angle, position, concentricity, etc.) at high speed.

4. Intuitive Presentation and Intelligent Determination: Measurement results are instantly presented in numerical, graphical reports (e.g., dimensioned charts with tolerance bands), and automatically compared with preset tolerances to give a quick and clear “pass/fail” conclusion.

III. Advantages of Flash Meter

-

Efficiency Leap, Capacity Enhancement: Seconds to complete the measurement, especially suitable for large quantities, multi-size workpiece rapid full inspection, release manpower, accelerate the production flow.

-

Simple Operation, Lower Threshold: No need for professional measuring personnel, ordinary employees can be simply trained to work, significantly reducing labor costs and training costs.

-

Objective Data, Trustworthy: Non-contact measurement avoids scratches on workpieces, automatic software analysis completely eliminates human error in readings, and the results are stable, reliable and traceable.

-

Powerful Functions to Meet Challenges: Easily handle objects that are difficult to measure with traditional tools, such as complex contours, tiny features (with high magnification), thin slices, and deformable workpieces.

-

Data-driven, Management Upgrade: Measurement data is automatically saved and exported to facilitate the generation of statistical reports (e.g. SPC analysis), providing solid data support for process control and continuous quality improvement.

IV. Typical application industries of the flash meter

-

Precision Electronics/Semiconductor: PCB boards, connectors, shields, chip carrier boards, etc.

-

Consumer Electronics (cell phones / computers): shell, frame, keys, camera modules, FPC flexible circuit boards, etc.

-

Automotive Parts: engine small parts, precision gears, stamping parts, injection molding parts, seals, etc.

-

Precision Hardware/Machining: springs, screws and nuts, precision stamping parts, cutting tools, powder metallurgy parts, etc.

-

Medical Devices: High precision parts, surgical instrument components, implants, etc.

-

Plastic Products: Precision injection molded gears, racks, structural parts, etc.

-

Research and Education/Reverse Engineering: Laboratory rapid measurement, sample size analysis, model data acquisition.

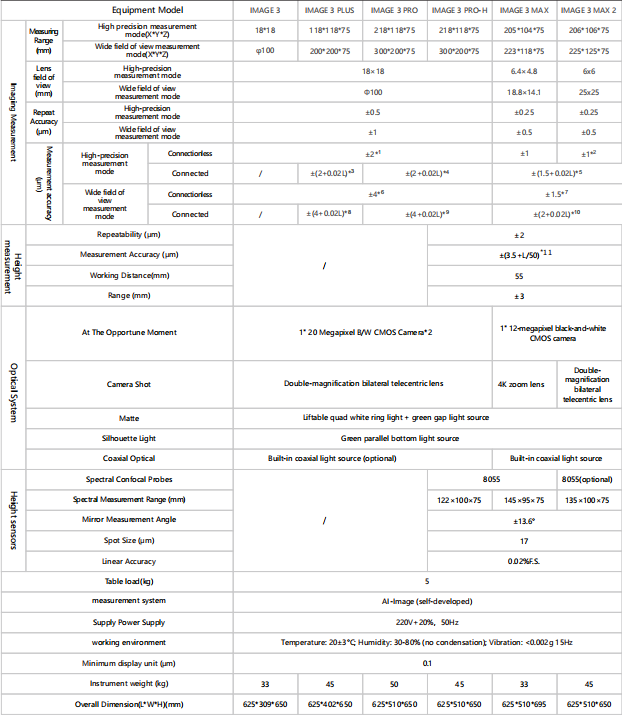

V. Flash Meter Parameter Guide

-

Measuring Range (FOV): The maximum workpiece size that can be covered in a single shot.

-

Core Accuracy (±μm): The absolute measurement accuracy that the device can achieve must match the tolerance requirements of your product.

-

Repeatability: The consistency of the results of multiple measurements of the same feature, reflecting the stability of the equipment.

-

Optical System Quality:

-

Camera resolution: the higher it is, the clearer the details are captured.

-

Lens: Telecentric lenses are standard, and their quality directly affects imaging accuracy and the degree of aberration-free.

-

Light source: ring light, coaxial light, bottom light and other types and adjustability, uniformity, critical to the quality of imaging.

-

-

Software Strength:

-

Are the supported measurement elements rich (point, line, circle, arc, angle, distance, position degree, contour degree, etc.)?

-

How is the automatic recognition capability (automatic edge finding, circle finding, line finding)?

-

Is the programming and batch processing function powerful (to realize automated pipeline inspection)?

-

Is the report output flexible and professional (report with diagram, customized template)?

-

Is the data interface open (SPC, database docking, MES system integration)?

-

By choosing POMEAS flash testers, you will gain: exponential improvements in QC efficiency; significant reductions in labor, training and overall QC costs; access to objective, consistent, traceable and high-quality measurement data; and a stronger, smarter product quality line of defense.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com