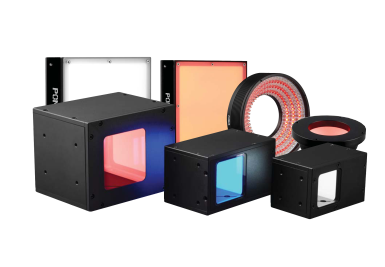

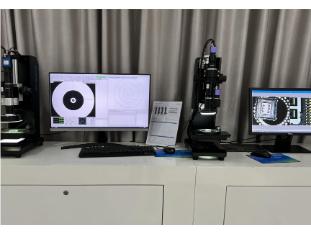

In the machine vision system, the type and characteristics of the light source directly determine the image quality and detection accuracy. At present, the mainstream light source types and their applications are different.

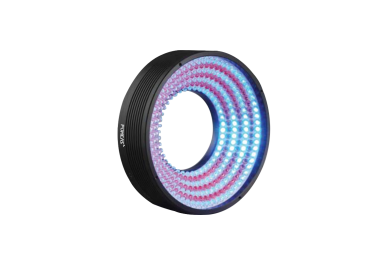

Ring light source is one of the most commonly used types, through the multi-angle uniform light, can effectively eliminate the shadow, highlight the object surface contours, suitable for PCB board component detection, cell phone screen defect identification and other scenarios. When detecting scratches on a cell phone screen, the ring light source projects light from all sides, and subtle scratches will be clearly presented due to reflective differences.

Backlighting uses transmitted illumination to place the object between the light source and the camera, creating a high-contrast silhouette effect that is particularly suitable for measuring the size of objects and detecting transparent or translucent materials. For example, in the dimensional inspection of glass products, the backlight can clearly outline the glass contour, which is convenient for the computer to make accurate measurements.

Strip light source is characterized by strong directionality and high brightness, and is often used to detect deep grooves, holes and other defects on the surface of objects. In the automobile engine block detection, strip light source with a specific angle of irradiation, can make the defects inside the cylinder block in the image of nowhere to hide.

The light from the coaxial light source propagates along the optical axis of the lens, which is suitable for detecting surfaces of highly reflective materials, such as metal mirrors and wafer surfaces. When detecting small cracks on metal mirrors, the coaxial light source can avoid reflective interference and make the cracks clearly imaged.

Different light sources play an indispensable role in machine vision. Choosing the right light source according to the material, shape and inspection requirements of the inspection object is the key to realizing efficient and accurate vision inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION