How to batch test bearing outer diameter? Realize zero misjudgment

Bearings as the core components of machinery and equipment, the accuracy of its outer diameter size directly affects the stability of equipment operation and life, so how to realize the outer diameter of the bearings of the batch, accurate, non-missing detection?

I. Bearing OD Measurement Requirements

1. Batch and high efficiency inspection: under the high speed operation of the production line, tens or even hundreds of bearings need to be inspected per minute to avoid capacity bottlenecks.

2. Micron-level precision guarantee: bearing outer diameter error should be controlled within 1μm, traditional tools due to human operation or environmental interference is difficult to achieve stable standards.

3. Full inspection without omission: omission of inspection may lead to batch quality problems, need to realize 100% coverage of the inspection, to eliminate the risk.

II. Measurement Program

1. Dynamic Real-time Measurement, Breakthrough Speed Limit

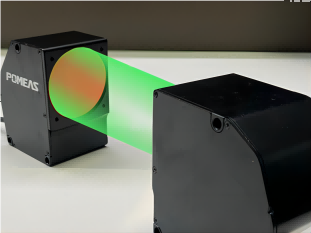

Adopting high-speed camera and intelligent algorithm, the equipment can capture the image data of bearings in motion in real time, without stopping or positioning, and detect 80 bearings per minute, the efficiency is far more than the traditional coordinate measuring machine or caliper.

2. Sub-micron Precision, Stable and Reliable

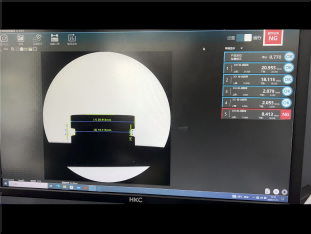

Combining high-precision optical system and sub-pixel image processing technology, the resolution of the equipment reaches 0.1μm, which can accurately identify the small deviation of the outer diameter, avoiding the fluctuation of accuracy caused by human error or mechanical wear.

3. Full Process Data Visualization and Traceability

Inspection data automatically generate reports, support size distribution, trend analysis and other visualization functions, and associated production batch, time and other dimensions, to achieve rapid traceability of quality problems.

4. Compact Design, Flexible Adaptation to Production Lines

The compact size of the device can be seamlessly embedded into the production line, applicable to the laboratory, workshop and other scenarios, reducing enterprise space and transformation costs.

Telecentric Measurement System helps customers to realize zero misjudgment measurement of bearing O.D. with the core advantages of “no leakage detection, high accuracy and full traceability”.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION