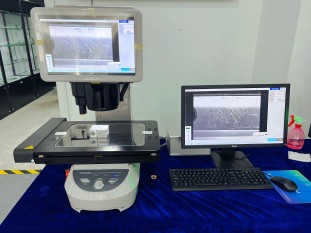

Can an image measuring instrument solve stamping parts/gears/screws inspection?

Detection Background:

Traditional inspection relies on tools such as calipers and projectors, which are cumbersome and susceptible to human error. And the image measuring instrument through the high-resolution lens to capture the full picture of the workpiece, combined with AI positioning technology, can be completed within 30 seconds of the complex contour of the batch measurement:

1, stamping parts / shrapnel detection: automatic identification of micron-level bending angle and thickness, real-time warning of deformation defects;

2, gear / screw precision control: synchronized analysis of tooth pitch, thread accuracy, concentricity and other 10 + parameters, to eliminate fit failure;

3, terminal connector quality control: in the 0.5mm pitch pins to achieve pin coplanarity ± 3μm level of repeated measurements, to protect the conductive reliability;

4, injection molded parts / die-cut parts quality control: accurate comparison of 3D models and physical contour difference, intercept shrinkage, flying edge and other process defects.

The one-button image measuring instrument integrates optical imaging and intelligent algorithms to realize intelligent process integration. After placing the workpiece, the system automatically completes the whole process of focusing, light source adjustment, feature recognition, data comparison and report generation.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION