Is 6 million points sufficient for scanning the outline of a mobile phone frame?

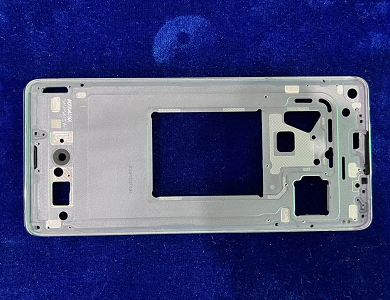

The line laser profile sensor scans the middle frame of a mobile phone and generates a 3D point cloud of 6 million points, which is a typical application of high-precision 3D measurement technology in consumer electronics manufacturing. The core purpose is to obtain the detailed 3D shape of the middle frame to meet requirements such as quality inspection, dimensional verification, or reverse engineering.

Principle: How does line laser profile sensing “perceive” three-dimensional shapes?

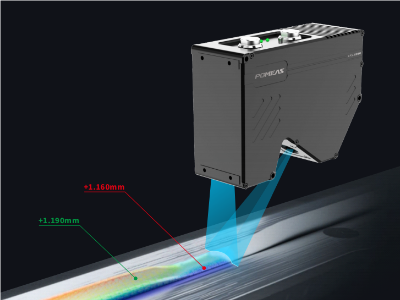

Line laser contour sensing scanning relies on the principle of laser triangulation. Its core components include a line laser emitter, an industrial camera, and a data processing unit. It works as follows:

1. Line laser contour sensing projects a continuous laser line onto the surface of the mobile phone frame. The laser line will deform due to the unevenness of the frame surface (such as corner radii, recesses, protrusions, etc.).

2. The mechanical structure moves the sensor, and the line laser profile sensor scans the entire surface of the middle frame row by row, ultimately accumulating a three-dimensional point cloud containing 6 million points.

Why is such high density necessary?

The smartphone midframe, as a core structural component (connecting the screen, battery, and back cover), directly impacts assembly sealing, appearance consistency, and user experience (such as grip feel) through its dimensional accuracy (e.g., length, width, height, hole positions, edge tolerances) and surface quality. A high-density point cloud with 6 million points is fundamentally designed to capture minute details, enabling a clear reproduction of the mid-frame's complex structure, such as the curvature of the R-角 edges (rounded transitions), the edge contours of button holes, the depth of antenna slots, and the subtle undulations of surface brushed textures. This prevents detail loss caused by insufficient point density (e.g., missing small indentations).

Operating Steps

1. Fixing and positioning: Fix the middle frame of the mobile phone on a precision platform (to prevent shaking during scanning). In some cases, reflective markers will be affixed to the surface of the platform or middle frame (for subsequent multi-angle stitching).

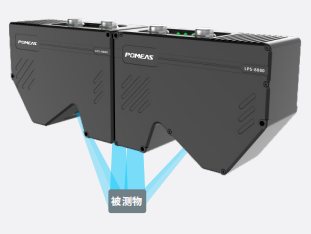

2. Multi-angle scanning: Two line laser profile sensors are driven by a robotic arm to scan the front, sides, and inner edges of the middle frame from all angles to ensure that there are no blind spots.

3. Point cloud stitching: Stitch point clouds from different perspectives (each perspective may generate 1-2 million points) using landmark matching or feature alignment algorithms to eliminate perspective bias and form a complete 3D point cloud.

4. Noise reduction and optimization: Remove noise points generated during scanning due to reflections (abnormal points caused by reflections from metal frames) and environmental interference (such as dust), and retain true details through smoothing algorithms.

Application Examples

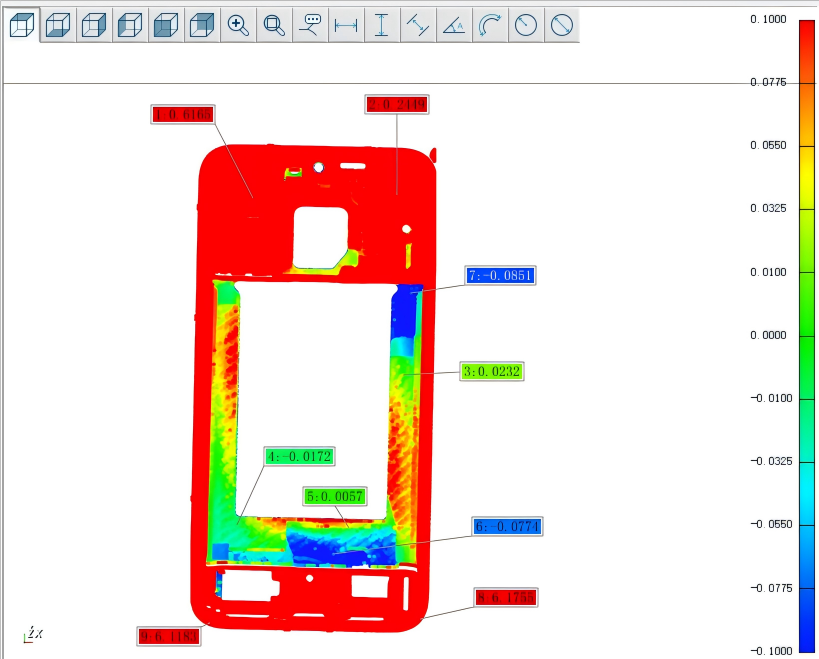

- Dimension tolerance inspection: Compare the point cloud with the CAD model of the design, automatically calculate deviations (such as hole position deviation, frame thickness error, R corner radius deviation), and determine whether it meets manufacturing standards.

- Surface defect detection: Identify surface scratches, protrusions (such as stamping residues), dents (such as collision damage), and other defects by analyzing changes in the Z-axis height of point clouds.

- Reverse engineering: If you need to replicate or improve the middle frame design, you can reconstruct an accurate 3D model based on point clouds, which can be used to modify mold parameters or optimize the structure.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com