The core differences between object-centered, image-centered, and dual-centered approaches

In the field of machine vision, especially in high-precision measurement tasks, telecentric lenses are a key tool for eliminating perspective errors. But when faced with object-side telecentric, image-side telecentric, and dual telecentric lenses, how can novice engineers quickly distinguish between them? In just one minute, we'll clarify the core differences for you!

Pain point: How to solve the “perspective error” of ordinary lenses

For example, when measuring the dimensions of parts on a conveyor belt, using a standard lens to measure the position of parts that move slightly forward or backward (change in object distance) will cause the image size to change, resulting in distorted measurement results. This is because the principal ray (the ray passing through the center of the aperture diaphragm) is not parallel to the optical axis on the object side or image side, causing the magnification to be sensitive to the object distance/image distance.

Industrial telecentric lenses use a special design (aperture diaphragm located at a specific focal point) to force the main light rays to be parallel to the optical axis, thereby eliminating perspective errors in a specific direction.

Image-side Telecentric

(1)The aperture diaphragm is located at the image plane. The main rays are parallel to the optical axis on the object side. In the visual scheme, the image size remains almost unchanged when the object distance changes!

(2)Applications: 1. Parts with slight height variations within the depth of field (e.g., vibrating conveyor belts). 2. Precise measurement of the object's dimensions is required, and the working distance may be unstable. 3. Examples: measuring the height of stacked coins or the dimensions of electronic components.

(3)Features: Light rays emerging from the lens are parallel, and the front aperture of the lens is usually large.

Object-side Telecentric

(1)The aperture diaphragm is located at the object focal plane. The main light rays are parallel to the optical axis at the image plane. In the detection scheme, even when there are slight installation errors or tilts in the image plane position (sensor position), the image size remains unchanged!

(2)Applications: 1. Camera installation may have slight deviations or vibrations. 2. Scenarios where precision of sensor position is not critical. 3. For use with sensors that are sensitive to installation (such as certain line scan cameras).

(3)Features: When light enters the lens, it is parallel, so the design of the rear end of the lens is more critical.

Double-sided telecentric lens

(1)The aperture diaphragm is located in the middle of the lens (where the object side and image side focal planes overlap). The main rays are parallel to the optical axis on both the object side and image side. It combines all the advantages of object side and image side telecentricity!

(2)Core advantages: Even when the position or tilt of the image changes, it can maintain stable image size, providing extremely low distortion and extremely high measurement accuracy.

(3)Applications: 1. Ultra-high precision dimensional measurement (e.g., semiconductor and precision parts inspection). 2. Scenarios that require overcoming both unstable working distances and camera installation errors. 3. Applications with extremely stringent image quality requirements.

(4)Features: Both ends of the light are parallel, and it is usually larger in size and more expensive.

Product recommendation

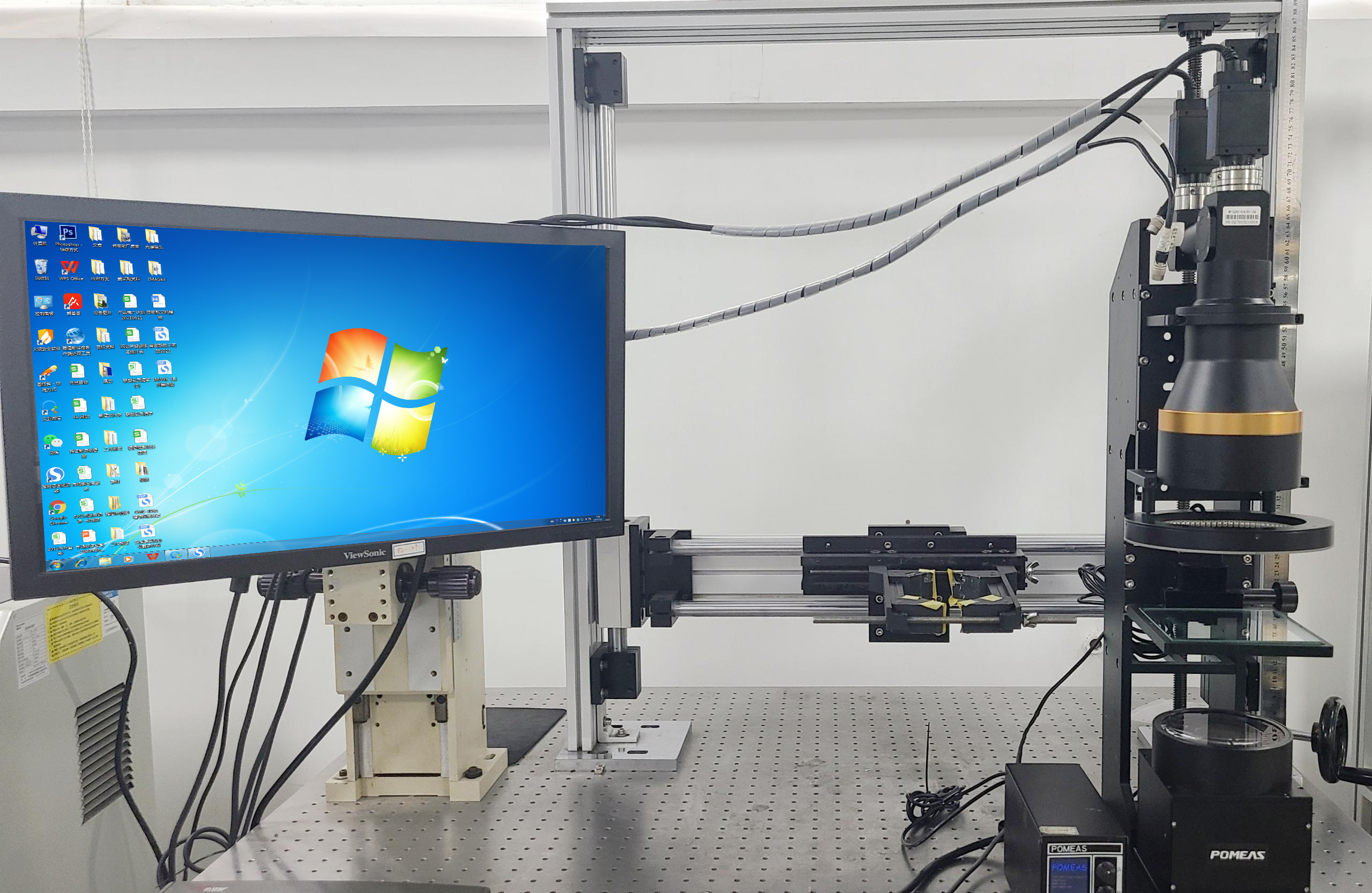

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com