In which scenarios is an autofocus video microscope not suitable?

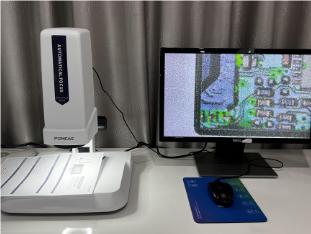

Autofocus video microscopes are efficient tools for industrial inspection, scientific research, and quality control. With their automated focusing capabilities and real-time video imaging, they significantly improve observation efficiency. However, not all scenarios are suitable for the use of such equipment.

Autofocus Video Microscope Optical Features

1. Fast autofocus: No manual focusing required, significantly improving detection efficiency.

2. Real-time video observation: Supports dynamic process observation and recording.

3. Limited depth of field: At high magnifications, the depth of field is shallow, requiring high sample flatness.

4. Dependent on surface texture/features: The autofocus algorithm relies on changes in brightness or structural features on the sample surface.

5. Sensitive to Vibration: Even minor vibrations may cause focusing instability or image blurring.

6. Adjustable Lighting: Four-zone adjustable lighting ensures uniform illumination, with automatic exposure reducing reflections and producing a soft effect.

Typical Application Scenarios

1. Batch product appearance inspection: electronic components (PCB solder joints, chip pins), precision parts (threads, small holes), and scratch and stain detection on jewelry.

2. Surface morphology analysis: Measurement of material surface roughness and scratch depth (requires 3D analysis software).

3. Dynamic process recording: Observation of micro-mechanical motion and material deformation under heat.

4. Educational demonstrations: Real-time display of microscopic structures for simultaneous observation by multiple users.

5. Laboratory routine testing: Rapid screening of biological samples and material microstructures.

Not Applicable Scenarios

1. Completely transparent/low-contrast samples: Glass, transparent plastic, unstained cells, etc., lack surface features, making it difficult for the autofocus system to find sufficient contrast for focusing.

2. Highly reflective or mirror-like surfaces: Highly reflective metals, mirrors, etc., cause strong light reflection, interfering with imaging and causing the autofocus system to malfunction or misjudge.

3. Deep holes or complex three-dimensional structures: Insufficient light in deep holes and obstructed views by internal wall structures make it difficult for the autofocus system to locate the effective focal plane.

4. High-speed movement or instantaneous changes: The autofocus system requires time to calculate and adjust, making it difficult to keep up with rapid changes, resulting in blurry images or missed critical frames.

5. High-temperature or extreme environment samples: Thermal radiation interferes with imaging, and high temperatures may damage the lens or sensor (most devices have an upper temperature limit of approximately 40°C–50°C).

6. Scenes requiring extremely large depth of field: Under high magnification, the depth of field is only micrometer-level, making it impossible to clearly display areas with significant height differences simultaneously.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com