In industrial automation precision inspection, the selection of telecentric lenses is crucial, directly affecting the imaging quality and measurement accuracy of the system. It is necessary to comprehensively consider the data in order to select the appropriate telecentric lenses for machine vision inspection solutions.

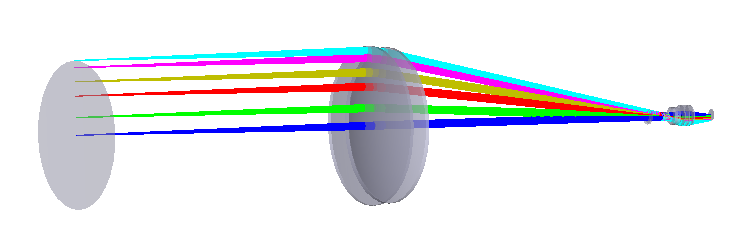

Telecentric Light Path

1. Working Distance

This refers to the distance from the front end of the lens to the surface of the object being measured. This must meet the spatial constraints of the application. For example, in some automated production lines, the space between equipment is relatively small. If the working distance of the telecentric lens selected is too long, it may not be possible to install it in a suitable position. If the working distance is too short, it may affect the observation of the object being measured. Therefore, before selecting a model, it is necessary to fully understand the size of the actual application environment to ensure that the working distance of the selected lens meets the requirements.

2. Field of View

The field of view refers to the size of the area of an object that a lens can see at a specific working distance. It is usually rectangular, and its formula is: field of view = sensor size / magnification. From this formula, it can be seen that the field of view is closely related to the sensor size and magnification. If the sensor size and magnification are known, the field of view size can be calculated, thereby determining whether the lens can cover the area of the object to be observed.

3. Telecentricity

This refers to the degree to which the main light beam deviates from parallel to the optical axis, usually expressed in degrees, such as < 0.1°. The smaller this value, the better, as it directly affects measurement accuracy and positional stability. In scenarios with extremely high requirements for measurement accuracy, such as the dimensional measurement of precision parts, if the telecentricity does not meet the standards, it may result in significant deviations in measurement results. Therefore, when selecting a lens, it is advisable to choose one with a smaller telecentricity.

4. Depth of Field

It refers to the range within which an object can maintain a clear image along the optical axis. This range is influenced by various factors such as aperture, resolution requirements, wavelength, and magnification ratio, and the depth of field of a telecentric lens is typically relatively small. This means that when using a telecentric lens, the position of the measured object along the optical axis should not vary too much, as this may result in blurred imaging. Therefore, when selecting a lens, it is important to choose one with an appropriate depth of field based on the range of possible positional changes of the measured object in actual applications.

5. Resolution / Resolution

This reflects the lens's ability to resolve details, which typically needs to match the size of the sensor pixels. Generally, the lens resolution should be slightly higher than that of the sensor. If the lens resolution is lower than the sensor, it will waste the sensor's performance and fail to capture the details of objects clearly. On the other hand, if the lens resolution is too high, it may increase costs and may also be limited by other factors, preventing it from fully utilizing its performance. Therefore, when selecting a lens, it is important to ensure that the lens resolution is compatible with the sensor pixel size.

6. Distortion

Geometric shape errors caused by imaging are typically required to be extremely low for telecentric lenses, generally less than 0.1%. If distortion is too high, it can cause the imaged shape of the measured object to deviate significantly from its actual shape, affecting the accuracy of measurement and detection. For example, during object contour detection, distortion may cause a originally regular shape to become irregular, leading to misjudgment. Therefore, the degree of distortion is a critical parameter that must be closely monitored during selection.

7. Interface

This is the part that connects the lens to the camera. Common types include C-mount, F-mount, and M42 mount. When selecting a lens, make sure that the lens interface matches the camera interface, otherwise the lens and camera will not connect properly. This is a basic but crucial point. If the interfaces do not match, the equipment will not work.

8. Sensor Size

This refers to the size of the camera sensor that the lens needs to support, such as 1/1.8“, 2/3”, 1", etc., and the lens image circle must cover the sensor. If the lens image circle cannot cover the sensor, it will result in incomplete or blurred imaging at the edges of the sensor, affecting the overall imaging quality. Therefore, when selecting a lens, it is important to clearly identify the size of the camera sensor and choose a lens that supports that size.

The selection of a telecentric lens is a process that requires systematic consideration. The seven key parameters—working distance, field of view, telecentricity, depth of field, resolution, distortion, interface, and sensor size—are all interrelated.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com